Intermediate-Level Makerspaces for High Schools

The availability of academic versions of professional level CAD/CAM software gives today’s students the ability to take an idea from a conceptualized ember and to vividly executed end-use product. Today’s students are eager to take their design skills and have a tactile, professional-level portfolio piece to impress college admissions and employers, which a high school makerspace offers.

What needs merit the investment in an intermediate-level makerspace?

- “High-Traffic” workflows, requiring remote management

- Need for equipment to support CAD/CAM programs

- Desire of students to create college-prep portfolio pieces

- Need to support complex projects, with highly-accurate geometries

Having access to intermediate-level makerspace tech allows students to:

- Plan CAD/CAM projects and test for real-world accuracy

- Iterate and refine designs more efficiently

- Create complex projects with higher accuracies

Our specialty is to advise our customers and create a future-focused makerspace plan that holds it’s value for the long-term and fits the needs of your program. By assessing your curriculum and the needs of faculty and students our tech consultants design a solution that makes the most sense for your budget.

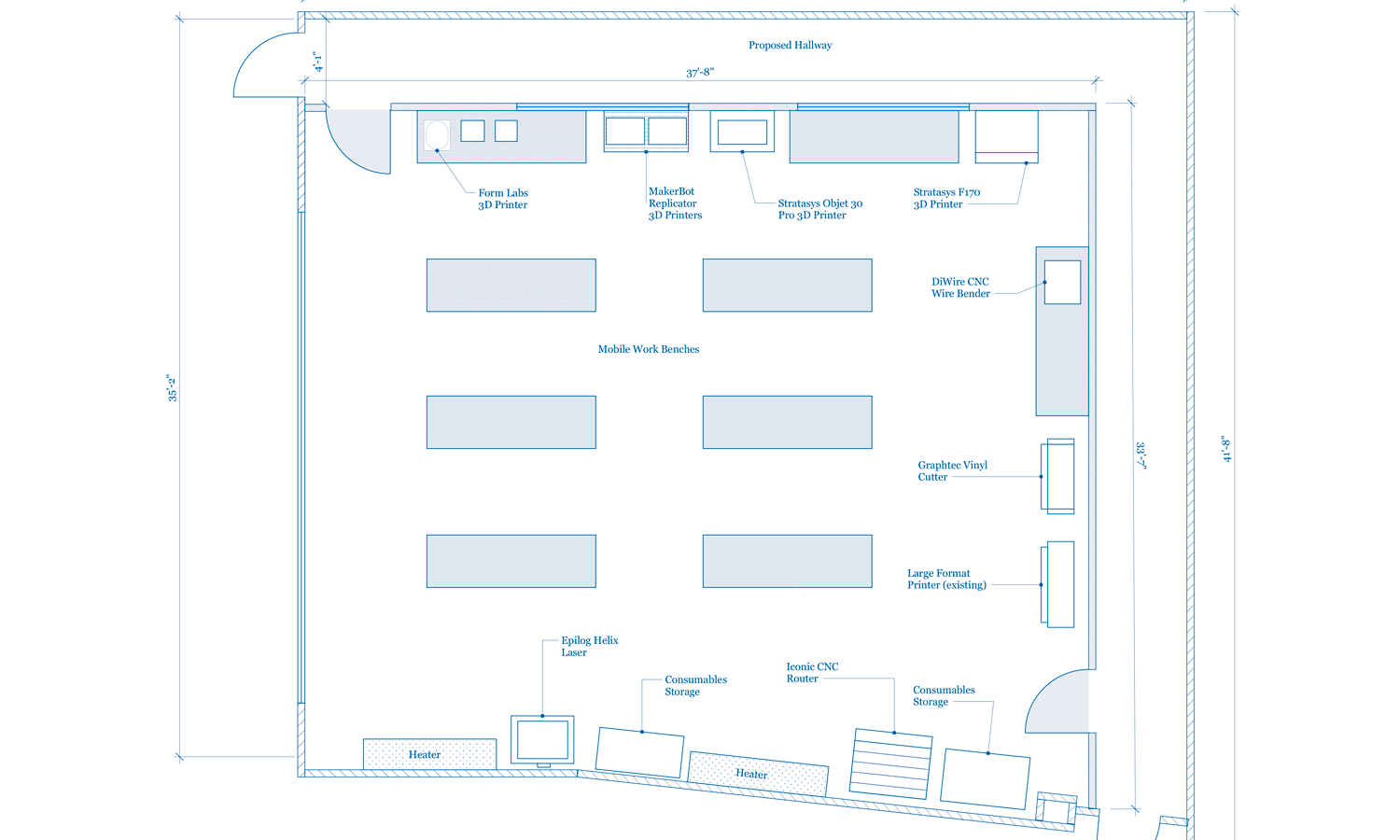

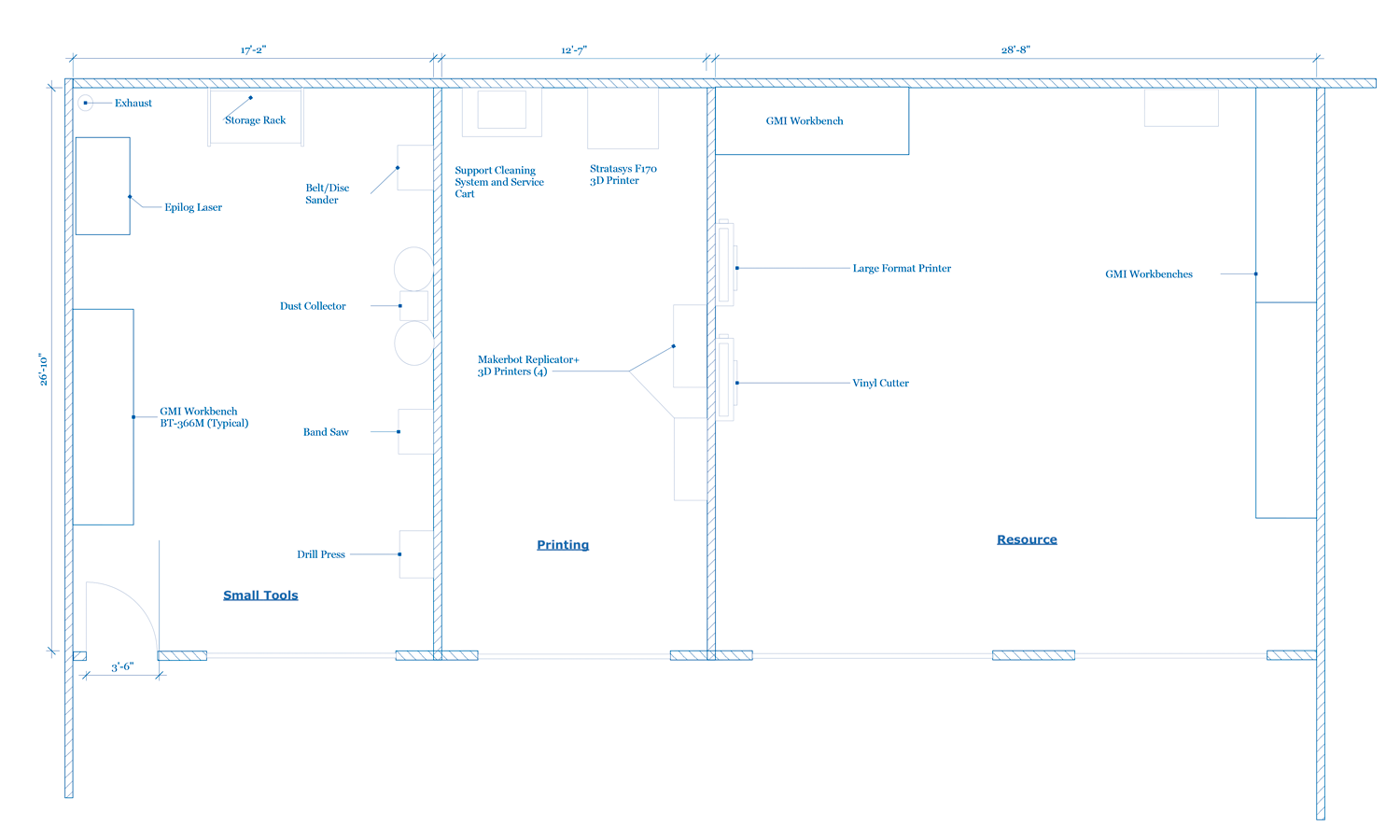

Intermediate Makerspace: Sample Plans

Slide to view examples of custom plans for intermediate academic makerspaces.