Transforming Education with Advanced Manufacturing Equipment

Technology in the manufacturing sector has changed dramatically over the last decade and will continue to progress, requiring the understanding of new and evolving skills. Therefore, our approach to supporting your machine technology program begins with the end in mind.

AET Labs partners with New England schools to provide the most relevant advanced manufacturing equipment that meets state curriculum standards, along with customized instructor training, conducted on-site by our local application specialists, that builds upon existing knowledge so your students are operating equipment safely and confidently.

Our team of specialists also offers free grant consultation services to help you fund advanced manufacturing equipment purchases. We have been involved in many successful grant applications for the Massachusetts Skills Capital Grant Program and Innovation Pathways.

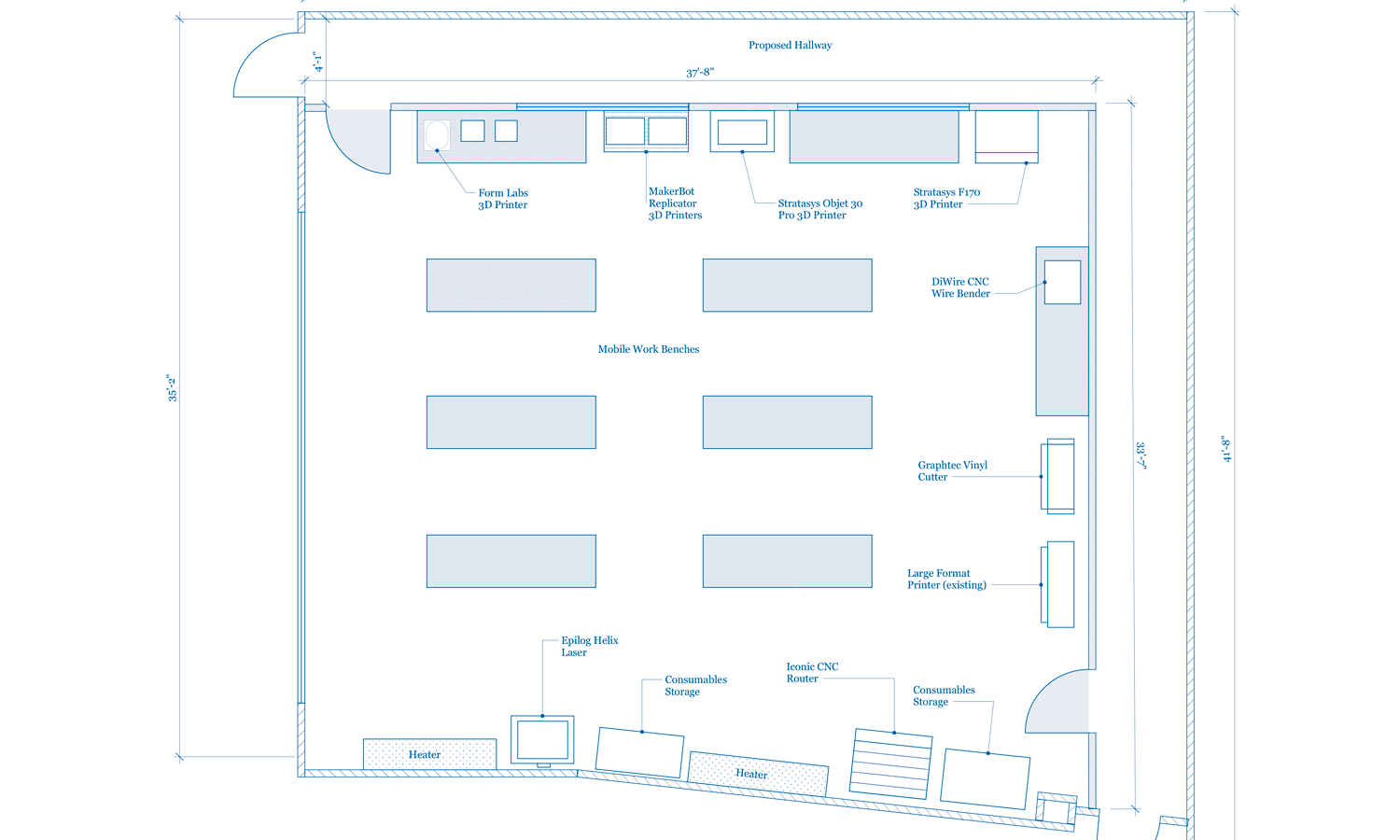

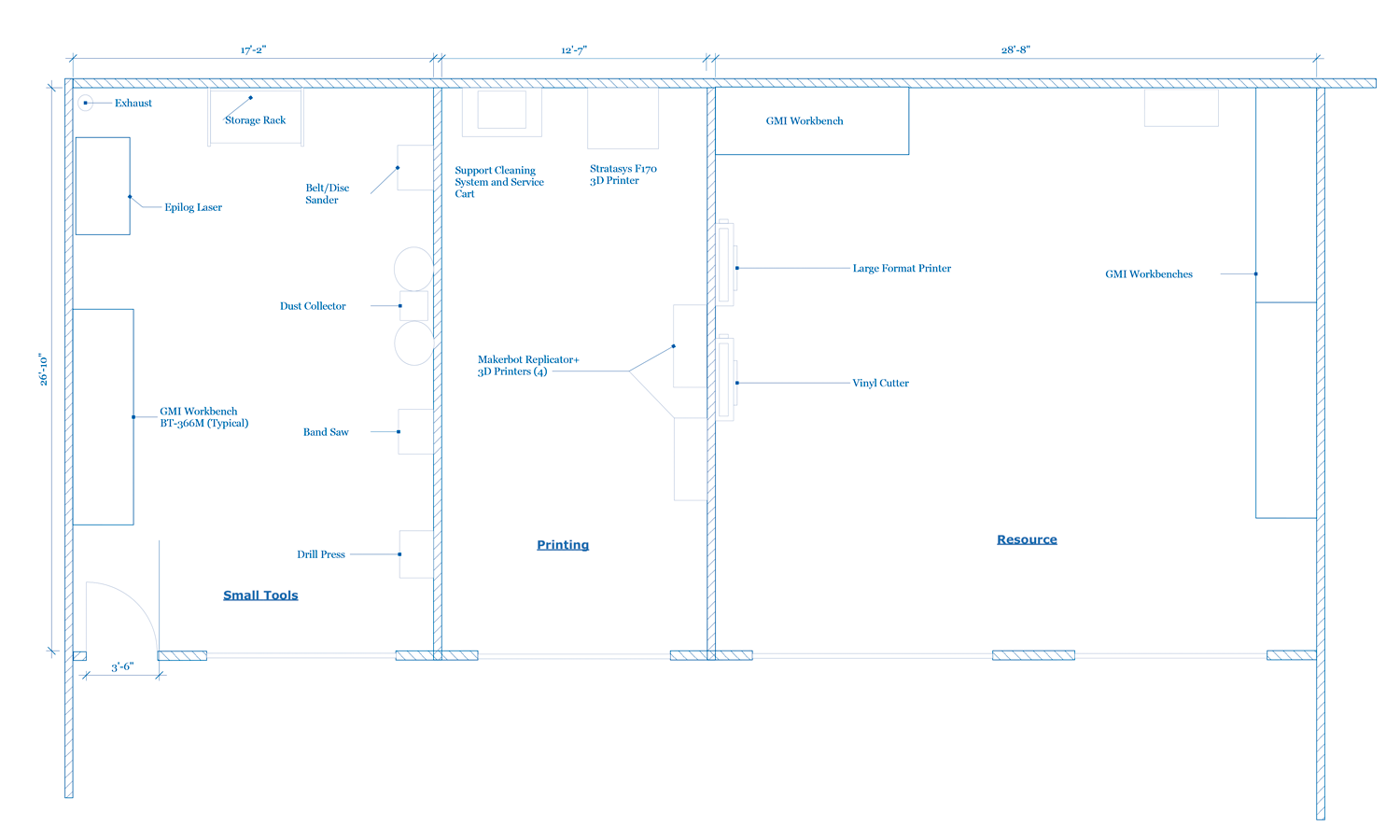

AET Labs can also help you design your advanced manufacturing lab if you are renovating or building a new space. Contact us for end-to-end lab solutions support!