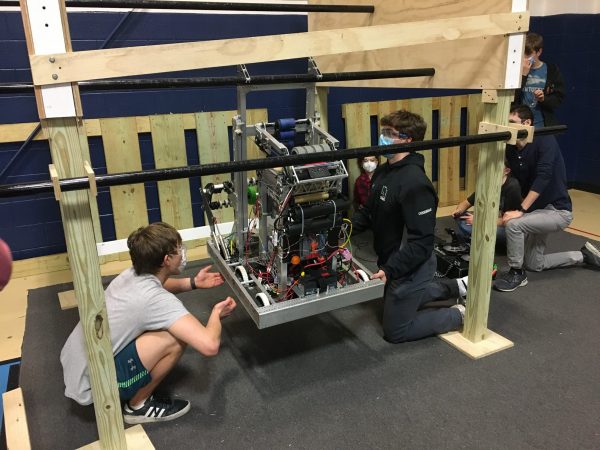

With the right equipment, students can get creative by making their own First Robotics parts to customize their robot. That's what First Robotics Team #2084 "Robots by the C" from Manchester Essex Regional Middle High School did for their 2022 competitions!

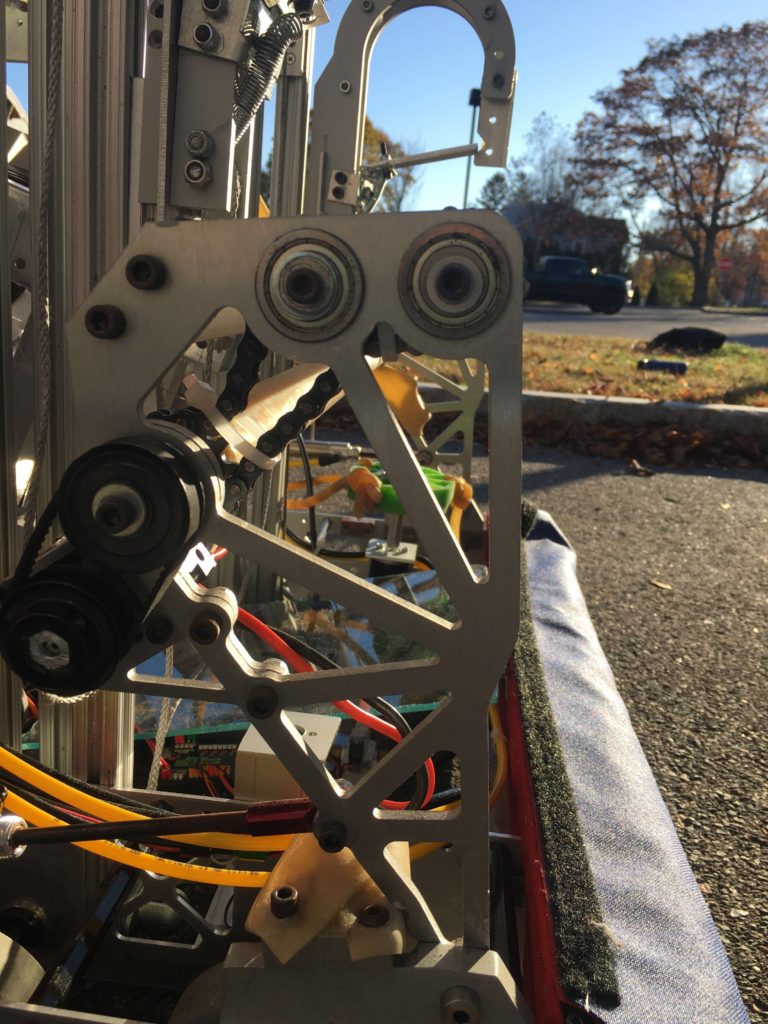

The students designed various parts for the ball intake and elevator mechanism, manufactured with an OMAX ProtoMAX Waterjet Cutter on 1/16" and 1/8" aluminum and a Stratasys J55 3D printer. Designing their own parts gave the students opportunities to think outside the box and have greater ownership and pride in their final robot.

Here's a Glimpse At The Production Of The Team's First Robotics Parts:

Advantages Of Creating Custom First Robotics Parts

Would you like to give your students opportunities to customize their robots? Giving students access to equipment to create their own parts comes with many advantages. They gain valuable skills when challenged to problem-solve as a team, explore their creativity, and test and iterate their design ideas. In addition, when they use equipment that is also used in the workforce, they improve their employability in advanced manufacturing, engineering, and industrial design careers. Plus, they'll have more options for creating a winning robot for First Robotics competitions!

Recommended Equipment for Creating First Robotics Parts

Here's some industry-relevant equipment that high school students can use to create their own First Robotics parts.

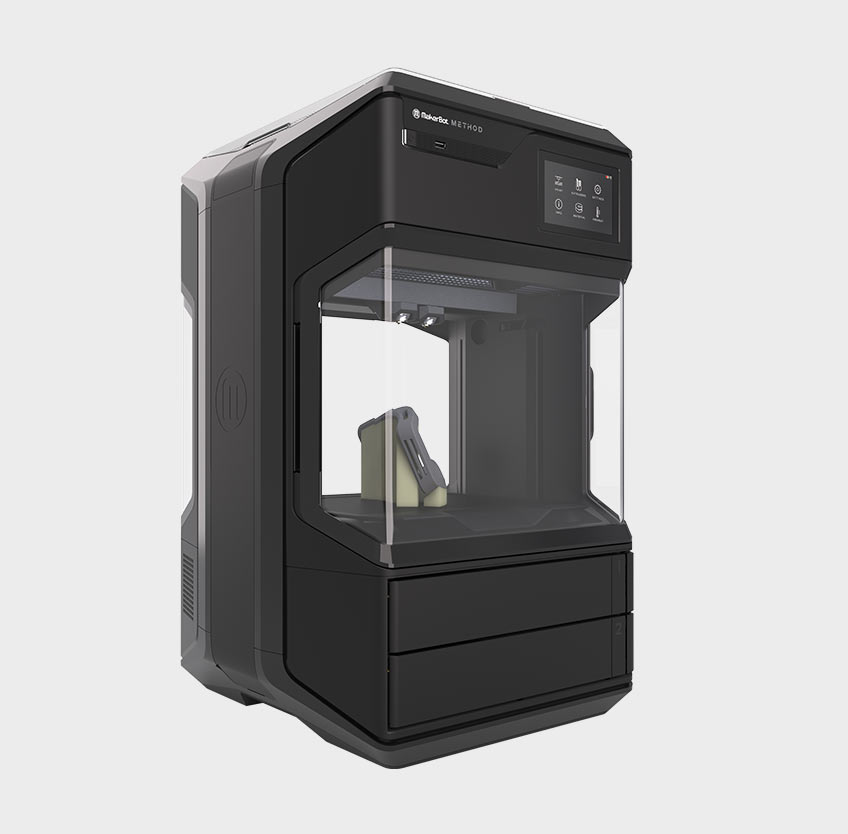

MakerBot and Stratasys 3D Printers

3D printing allows students to rapidly prototype ideas for parts during the design phase. They can also create made-to-order parts when they realize they need something specific that is difficult to obtain when outsourcing their parts production. First Robotics teams have 3D printed many parts, including gears, treads, wheels, brackets, sprockets, strain relief, spools, and phone mounts.

The MakerBot Method X gives students an introduction to industrial 3D printing and delivers manufacturing-grade parts with advanced engineering materials.

The Stratasys F123 series produces accurate parts with more material options to create a range of robotics parts.

Tormach CNC Machines

For sturdier high-quality parts, students use CNC machines, like mills, routers, and plasma cutters, to create components in aluminum and steel. First Robotics teams have used CNC machines to create brackets and mounting components essential to the inner workings of the robots as well as more complex parts like sprockets and organic shapes. Tormach CNC Plasma Cutters can also be used to create large foundational parts like the robot chassis. Teams can produce parts at scale with CNC machines that are high quality and more precise than using a drill press or bandsaw.

Tormach CNC machines are used in the workforce and are appropriate for high school students to use for creating high-strength First Robotics parts.

ProtoMAX Waterjet Cutter

For even more versatility in sturdy materials for parts, First Robotics teams use waterjet cutters to create components, including grappling hooks and ball intakes. The ProtoMAX Waterjet Cutter works well for prototyping and low-volume cutting of almost any material approximately one inch thick.

The ProtoMAX Waterjet Cutter cuts through nearly any material, allowing students to produce structural components in metal and carbon fiber with superior strength and performance.

Epilog Laser

To finish out their robots, students use laser cutters to create lightweight components. Laser cutters can cut through many materials including plexiglass and lexan for framing and guarding and other light-duty applications.

The Epilog Fusion Edge Laser is a high-quality system that is accessible for students to use, and comes in a compact desktop format.

Graphtec Vinyl Cutter

Students can have a lot of fun using vinyl cutters to trick out their robots with colorful graphics created into stickers and decals. They can design their own images to really personalize their robot and stand-out in the competition!

The Graphtec CE7000 Series Vinyl Cutter is a large-format roll-feed cutter/plotter that is easy to use and produces superior quality decals, stickers, and signage.

Do you want your students to create their own parts for robots? We can help you find the right equipment for producing First Robotics parts and grants to help fund the equipment. Contact us to get started!