We’ve seen first-hand the thrill of robotics teams in competitions - and all that leads up to that moment. There’s the excitement and creativity that comes with designing and building the robot. Plus, the problem-solving, creativity, and team-building that forms among the students. And finally, the accomplishment and confidence in seeing the robot they’ve built be put into action.

As a leader of a robotics program, you want to provide the guidance and mentoring these students need, along with access to the best equipment that will allow them to explore their creativity and win their competition!

A waterjet cutter is a reliable, powerful tool to offer to students building robots. For example, the ProtoMAX Waterjet Cutter cuts through nearly any material, allowing students to produce structural components in metal and carbon fiber that have superior strength and performance. Thanks to the versatility, students can see their creativity in action, producing custom parts for designs they create.

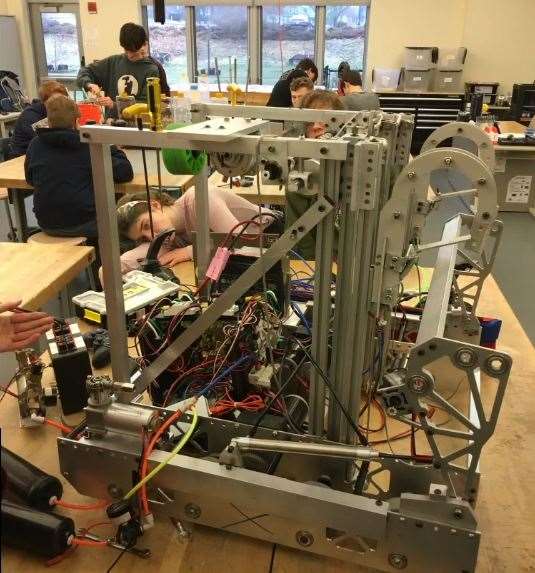

Want to see the ProtoMAX Waterjet Cutter in action? Take a look at these photos from the Manchester-Essex Regional High School robotics team. They used the machine to create parts for a grappling hook and ball intake!