As industries in New England face a rising demand for skilled workers, CTE programs play a crucial role in bridging the gap. These programs equip students with practical skills for high-demand fields in manufacturing, healthcare, and robotics. But how can schools attract students to these transformative opportunities?

One answer lies in the tools they use. By integrating cutting-edge equipment, CTE programs can foster engagement, meet industry needs, and position themselves as leaders in technical education. Modern equipment enhances learning and inspires students to imagine a future filled with possibilities.

The benefits of incorporating such equipment extend far beyond the classroom. From staying aligned with industry standards to engaging students during exploratory phases and creating clear pathways to in-demand jobs, high-tech tools play a pivotal role in driving enrollment and preparing students for success. Let’s explore how this investment makes a difference.

In today’s job market, many industries face significant labor shortages, heightening the need for skilled workers ready to contribute from day one. Employers increasingly prioritize candidates with hands-on experience in the latest technologies, and CTE programs that provide this training give their students a distinct competitive edge.

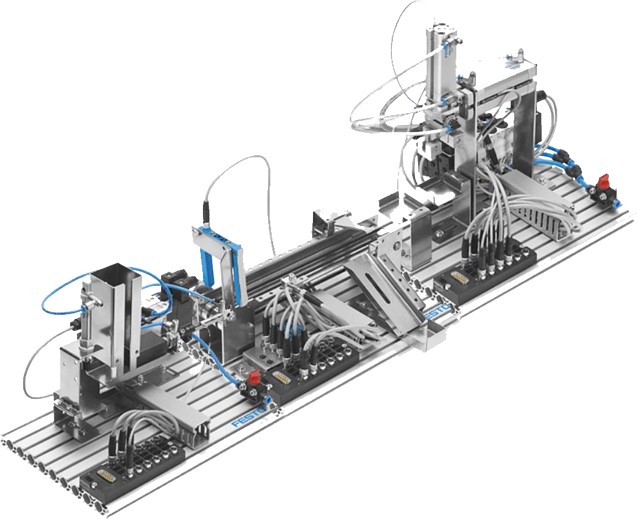

For instance, as the automotive industry transitions toward sustainable solutions, training students in electric vehicle maintenance and repair ensures they are prepared to meet the demands of this evolving sector. Similarly, automation is reshaping manufacturing, making it critical for students to gain experience with robotic systems. Training in robotic machine tending equips students with the skills to program, operate, and maintain advanced technologies, positioning them as highly valuable employees in a rapidly transforming industry.

By offering this practical, industry-aligned training, schools ensure their graduates are workforce-ready, helping to address labor shortages while making their programs more attractive to students and parents alike.

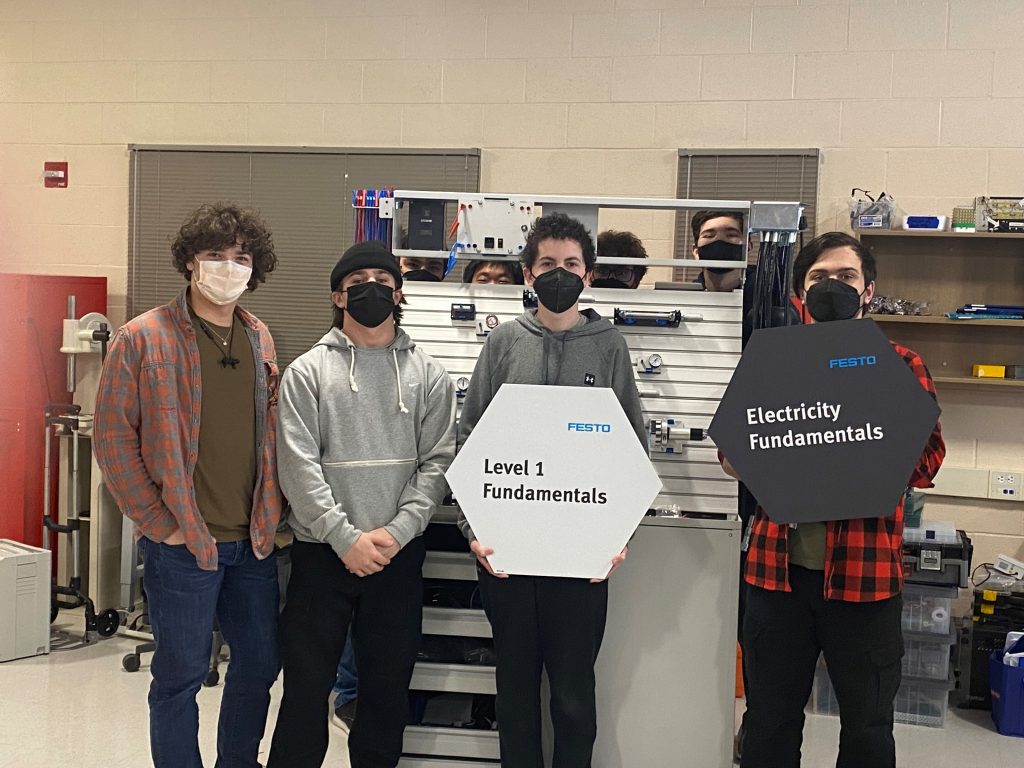

States across New England are increasingly prioritizing advanced technical skills in their CTE standards, reflecting the growing demand for expertise in automation, robotics, and mechatronics. For example, Massachusetts has updated its standards to emphasize competencies like robotic machine tending in advanced manufacturing programs. Similarly, Connecticut’s CTE framework highlights robotics, automation, and mechatronics as key areas of focus for manufacturing, preparing students for careers across industries.

By adopting equipment that aligns with these updated state standards, schools demonstrate their commitment to providing industry-relevant education. This approach not only ensures compliance but also positions schools as leaders in technical training, capable of preparing students for the challenges of a rapidly evolving workforce.

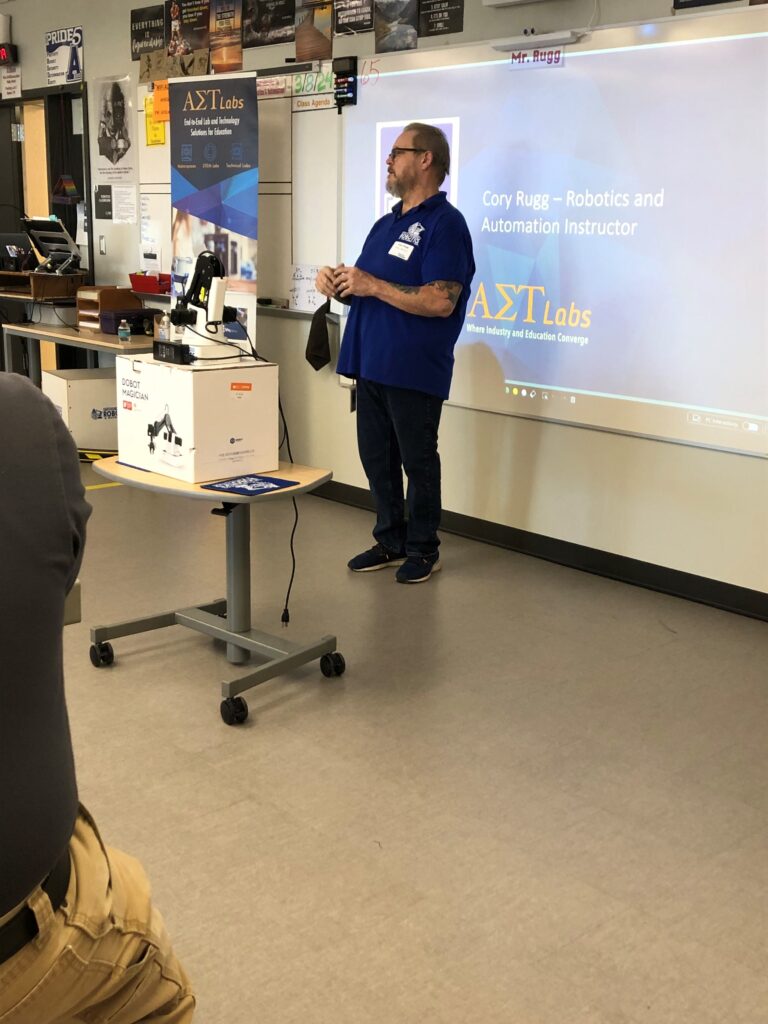

The freshman exploratory phase is critical for sparking interest in CTE programs. Hands-on, high-tech experiences during this period can leave a lasting impression and play a significant role in enrollment decisions. Modern equipment makes learning exciting and demonstrates the relevance of technical fields to today’s job market. Engaging technology help students see their potential for future careers.

For example, robotic arms used in robotics and automation programs allow students to program and operate robots, demonstrating real-world applications in industries like manufacturing and healthcare. This tangible, interactive experience showcases the relevance of robotics and inspires students to envision themselves working in cutting-edge roles. Similarly, mixed-reality welding simulators revolutionize how students learn welding techniques by offering a safe, engaging, and highly interactive practice environment. These simulators mimic real-world conditions while providing instant feedback, making the learning process both effective and enjoyable.

By introducing fun technology during exploratory, schools create memorable experiences that students are eager to share with peers and parents. This enthusiasm drives interest and enrollment, solidifying the program's reputation as an exciting and future-focused educational pathway.

CTE programs are pivotal in preparing students for meaningful careers in high-demand fields by integrating industry-recognized certifications and cutting-edge equipment into their curricula. Certifications validate practical skills and knowledge, giving graduates a significant advantage in the job market and attracting students and families to enroll in these programs.

For example, robotics certifications demonstrate proficiency in programming and operating robotic systems, making students highly sought after in industries such as manufacturing and engineering. Similarly, certifications in additive manufacturing open doors to rapidly expanding fields like healthcare, aerospace, and architecture.

By aligning certifications with industry needs and providing hands-on experience with cutting-edge technology, CTE programs ensure students are well-prepared to "hit the ground running" in their chosen careers. This alignment not only enhances student outcomes but also positions schools as leaders in technical education, fostering increased enrollment and engagement.

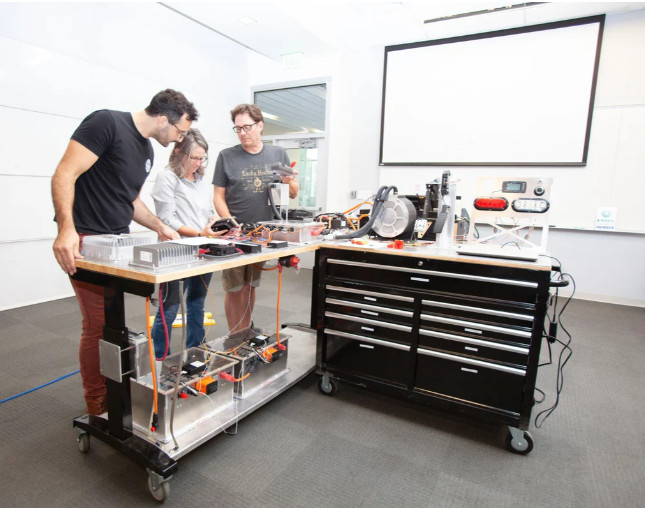

Modern equipment enhances education and serves as a powerful recruitment tool. It demonstrates a school’s commitment to excellence and future-ready learning. From a parent’s perspective, industry-relevant equipment like robotic arms, CNC machines, and 3D printers provide reassurance that their children are acquiring practical, career-ready skills. Seeing such equipment during school tours builds confidence in the program’s value and future opportunities for their students. High schoolers, on the other hand, are naturally drawn to cutting-edge technology. They see that they can have fun learning and get hands-on experience with modern technology.

Schools equipped with state-of-the-art technology position themselves as leaders in technical education, showcasing their commitment to career readiness. This not only attracts motivated students but also fosters valuable partnerships with local industries. Additionally, investing in advanced equipment strengthens trust and credibility with district administrators, employers, and community leaders, further enhancing the program’s reputation.

With the right equipment, CTE programs can capture attention, build credibility, and solidify their reputation as a gateway to in-demand careers. At AET Labs, we specialize in helping CTE programs integrate modern equipment that aligns with workforce needs and inspires students. Our technology consultants partner with schools to assess goals and recommend tailored solutions.

Take the next step today. Contact AET Labs to schedule a consultation and explore how we can help transform your classrooms and boost enrollment. From meeting updated standards to creating engaging learning experiences, we’re here to guide you every step of the way.

Incorporating cutting-edge equipment is more than an upgrade—it’s a strategic investment. Modern tools boost student engagement, prepare graduates for in-demand jobs, and position schools as leaders in technical education. By partnering with AET Labs, schools can ensure their programs are equipped to meet industry needs while inspiring the next generation of skilled professionals.