Incorporating 3D printing technology in college engineering programs creates endless options for teaching valuable skills like design thinking, problem-solving, and innovation alongside engineering concepts. To help you expose your students to these industry-relevant skills, we've compiled five 3D printing projects for engineering students. Each project comes with lecture ideas, project parameters, and design files that you can use in your courses.

3D Printing Ideas for Students

1. Build Gear Systems

Students build a 3D gear system that uses more than one gear to produce motion. They learn how to build a gear system in CAD, convert 2D gear drawings to 3D models, and design systems with 3D printing technology in mind, including minimum tolerance and material thickness. For a lecture guide, lessons, case studies, STL files, and videos, navigate to project 3.15 in this guide.

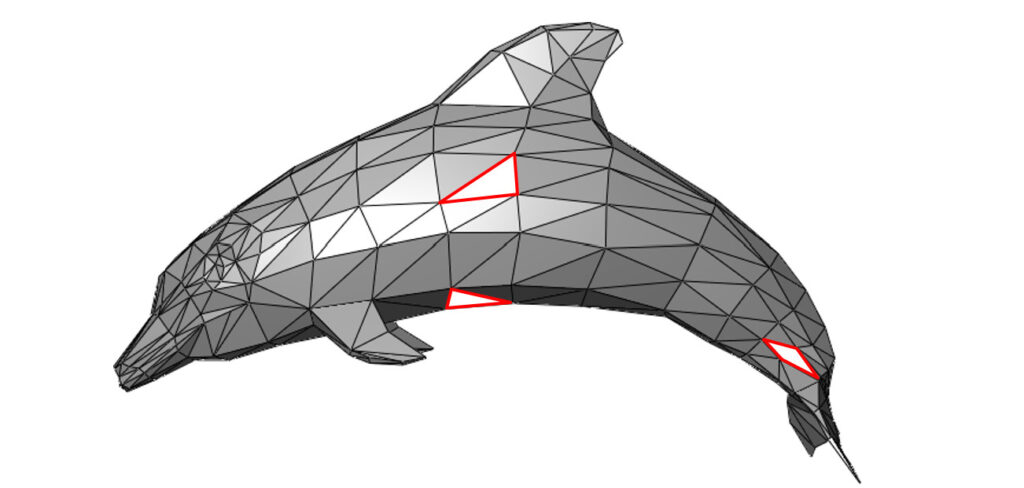

2. Design 3D Mesh Structures

Students learn how to define essential geometry terms related to a 3D mesh. They then create smooth and detailed 3D structures, repair a 3D mesh, and prepare files for print. They can either improve upon an existing file or design a product from scratch. For a lecture guide, lessons, STL files, and videos, navigate to project 3.12 in this guide.

3. Create Dynamic Surfaces and Chains

Students learn about 3D printing dynamic surface concepts, which are arrays of connected surfaces in which the movement of one surface moves all other surfaces in a predictable way. They learn to nest and orient 3D models on the build tray to conserve space and materials to make more space and cost-efficient use of 3D printing technology. For a lecture guide, lessons, case study, STL files, and videos, navigate to project 3.13 in this guide.

4. Explore 4D Printing

Students learn what 4D printing means and imagine its potential impact on the design process. They are challenged to design and 3D print an item that moves something. It must be a mechanical object that shifts forces from one point to another, is a closed system, and is created in a single 3D print without assembly. For a lecture guide, lessons, STL files, and videos, navigate to project 3.7 in this guide.

5. Participate in Community Competitions

GrabCAD hosts challenges related to mechanical engineering, sponsored by organizations like NASA and Stratasys, and students can win cash prizes! For example, one competition was sponsored by NASA and challenged participants to design innovative concepts for the Artemis program to deliver pressurized logistics (food, supplies, water, repair items, tools, etc.) to the moon's surface. Check out active and past competitions here.

3D Printers for Engineering Programs

When it comes to selecting which 3D printer to add to a lab, the decision depends on how you intend to use the printer within your course or research. There are many types of 3D printers on the market, each with its own unique capabilities and features.

In general, we recommend Stratasys 3D printers for higher ed labs. Stratasys is a leader in 3D printing technology, and its line of reliable printers offers an array of options to meet your teaching or research needs. Here are a few of Stratasys' many 3D printers for you to explore:

Stratasys F123 Series

The Stratasys F123 Series printers are reliable FDM printers that are known for their ease of use, built-in safety features, and efficiency. They produce accurate small-batch custom end parts, jigs and fixtures, and prototypes. These printers are compatible with many material options, including PC-ABS, PLA, ASA, and more.

Stratasys J55 Prime

If you have projects using color or multi-material designs, the Stratasys J55 Prime is the best option. This printer can print vivid multi-color and multi-material items. It offers materials with access to over 500,000 colors, including Pantone-validated colors and Voxel printing capabilities. MIT mechanical engineering students use the J55 each year in the Toy Product Design course.

Stratasys Origin One

The Origin One is a resin 3D printer that uses P3 technology. It can create accurate and consistent end-use production parts using a range of high-performance materials, including heat-resistant, impact-resistant, and elastomers. It also works with more unique, certifiable materials from Loctite, Henkel, and others, providing options to test and develop your own materials for research. Get a deep-dive into the Origin One here.

Incorporating 3D printing projects for engineering students in your coursework will give students invaluable skills for any engineering-related career path. 3D printers are also a lot of fun for students and will get them engaged by seeing their ideas come to life!

If you want to upgrade or buy a new 3D printer for your engineering program, please contact us! We work closely with professors and lab directors to bring 3D printers to New England colleges and universities, with local training and service options if needed.