PLCs (programmable logic controllers) are one of the most critical components in industrial automation. PLCs are industrial computer systems that are modular and designed to automate customized control processes, supporting control motors, pumps, lights, fans, circuit breakers, and other machinery found in factories and industrial plants. Students benefit from understanding PLCs because they are essential to jobs as engineers and technicians who work in various fields, such as manufacturing, robotics, automation, and renewable energy. Learning how to program and use PLCs also helps students develop logic, problem-solving, troubleshooting, and system design skills.

Becoming proficient in selecting, programming, and applying programmable logic controllers can require a vast amount of knowledge and time. The subtle differences between popular brands, programming languages, power supplies, I/O blocks, cable connectors, mounting options, etc., can quickly overwhelm almost anyone. A PLC can seem like a little "black box" mystery to some instructors.

However, approaching this technology in a step-by-step manner, makes it possible to overcome some of the perceived obstacles and will make some quick wins for you and your students. In collaboration with Festo, an AET Labs partner, and local teachers, like Dean Lepkowski at Monty Tech in Massachusetts, we've developed a PLC training program for engineering and robotics and automation CTE programs to incorporate into their curriculums.

Step 1: Introduction to Automated Systems

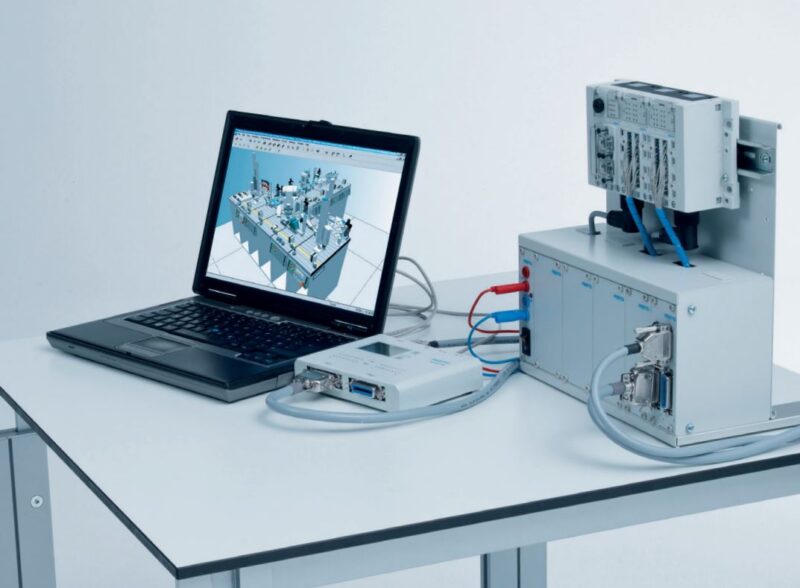

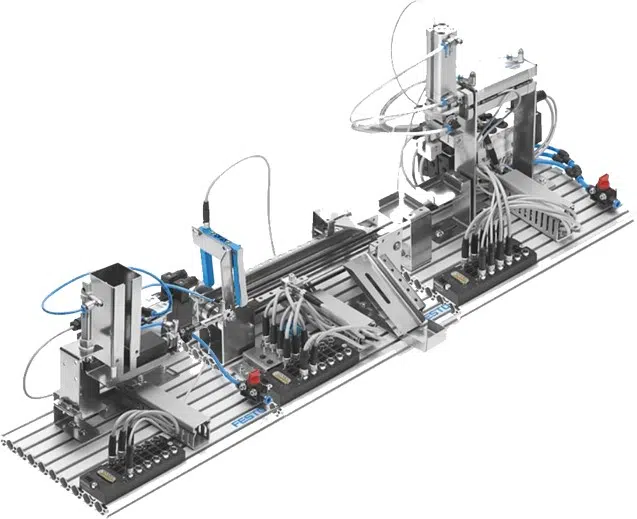

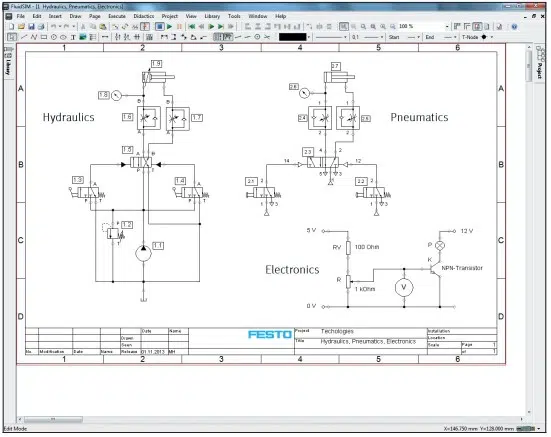

The Festo MecLab Training System gives students a solid starting point for understanding how automated systems work. In conjunction with FluidSIM software, students can simulate electropneumatic circuits through schematic design, as well as a "soft" logic controller, giving them a fundamental understanding of inputs, logic, and outputs using a Sense --> Think --> Do framework. Understanding the basics of how automated systems work will give students more confidence to dive deeper.

Step 2: Hands-On with Mini Controllers

Once students become proficient in operating the Festo MecLab, they will become curious and ask questions like "What else can I automate?" or "Can I get all three stations to operate together?" While it has been proven with FluidSIM that this can be done, it isn't something we recommend. The Boolean logic used within the soft logic controller quickly becomes overwhelming and messy. This is where a PLC comes in, and a whole new world of automation begins.

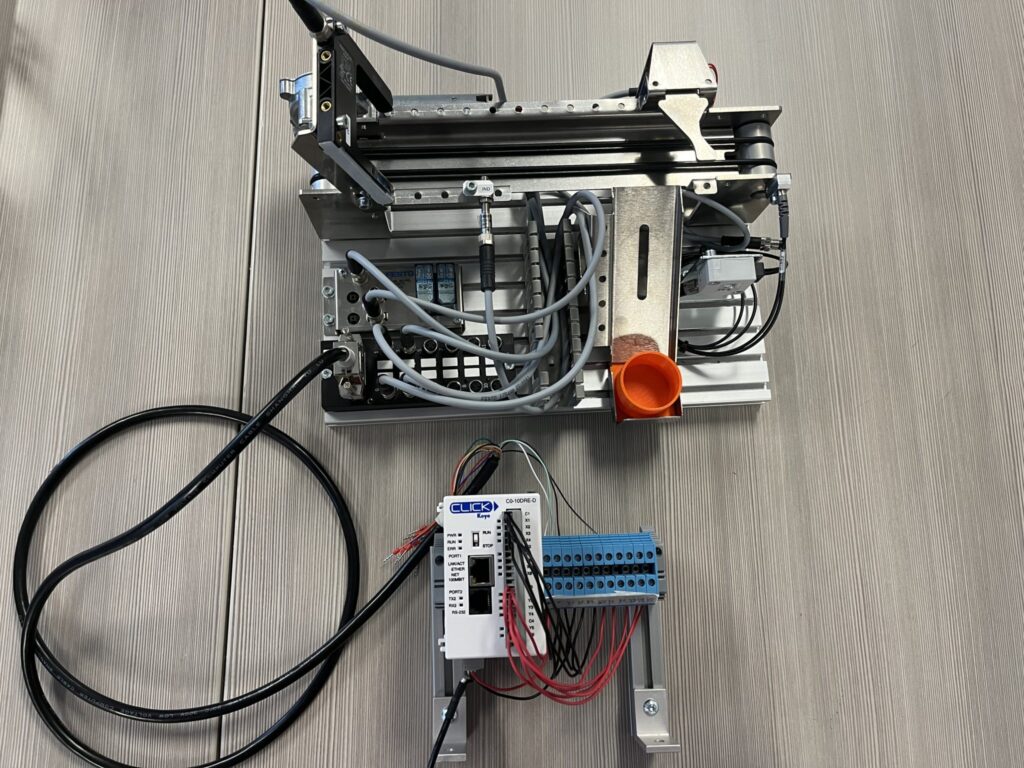

The fastest and least expensive solution is to use a mini controller (See "PLC Starter Solution for MecLab" post). Several reputable brands will do the job. For example, the Click PLC is inexpensive, easy to use, has a good selection of accessories, and is readily available. Using a mini controller can prove useful for small, non-complex automation projects that aren't critical in nature. By allowing students to directly wire, program and apply a cheap PLC system, they'll get a valuable understanding of basic PLC system architecture.

Step 3: Advance with PLC Training Systems

However, this is just the beginning of the learning path. Mini controllers, like the Click PLC, are a good stepping stone, but instructors will need their students to absorb much more knowledge to become proficient in PLCs. Industry 4.0 technology is the future, and in order for students to be I4.0 ready, they need experience using PLCs used in automated factories and industrial plants. Allen Bradley and Siemens are the dominant controllers used in the workforce.

Timed task-completion is the name of the game. Once a student knows how to wire a PLC system, is it necessary that they do it every time? Could their time be spent on more productive learning tasks? Festo believes so, which is why they created various PLC training systems, which incorporate Allen Bradley and Siemens technology. These unique configurations include thoughtfully designed, pre-wired PLCs that include built-in power supplies, input/outputs with 4mm quick connect safety leads, Syslink cable connectors, universal connection boards, creative mounting options, and a ton of pre-engineered accessories, which takes the guesswork out of making sure everything works together.

Curriculum is central to each Festo PLC training system. Instructor guides and student manuals are included, ensuring that instructors don't need to be an expert in this subject but instead motivators and facilitators. A cloud-based content learning management system, Festo LX, allows for more dynamic curriculum that can be easily managed by instructors and delivered to the student anytime, anywhere.

The sky is the limit in creating a robust PLC training program. It's not rocket science, but it can certainly be an intimidating subject to teach. So our recommendation is to ask for help along the way to give your students the best tools possible to ensure a successful future working in engineering and automation!

AET Labs can support your New England PLC training program through professional development, grant consultations to obtain training equipment, or connecting you with local instructors successfully teaching PLCs in their high school CTE programs. Contact us today!