Designed to teach the theory and techniques of electric motor controllers

The Industrial Controls Training Systems are designed to teach the theory and techniques of electric motor controllers. They allow students to select and mount control devices to form typical control circuits, and to troubleshoot them once a fault is inserted. The systems offer unique controls training possibilities, are modular, and include insertable faults.

The Industrial Controls Training Systems comprise four basic systems, each covering a particular topic that deals with various aspects of industrial controls equipment operation. The following systems are available:

- Basic Controls, Model 8036-1, provides students with a complete basic training in motor controls.

- Programmable Logic Controller, Model 8036-2, introduces students to PLCs for motor operation control.

- Motor Drives, Model 8036-3, introduces students to dc and ac drives.

- Sensors, Model 8036-4, introduces students to photoelectric and proximity switches.

Optional study: TP1221-P Basic Motor Control Technology (Portable)

The Basic Motor Control Technology learning system builds knowledge and skills in the fundamentals of industrial electric motors controllers. A wide range of hands-on learning activities optimize the

development of technical knowledge, as well as soft and troubleshooting skills – the prerequisites for a good preparation for the workplace. More information can be found here: TP1221-P

Although the TP1221-P does not cover the depth of topics compared to the above 8036 Industrial Controls Training System, it is enclosed in a rugged case fitted with sturdy wheels, has a telescopic handle for easy transportation and integrates with other Festo training systems including:

- Electrical wiring

- Skills Conveyor

- PLC Edutrainer

- Sensors Package

Features & Benefits

- Extensive array of modules makes it possible to create setups filling a large number of training needs

- Wide variety of modules representative of control components found in the industry

- Comprehensive curriculum including student manuals with hands-on exercises and instructor guides

- Includes safety features such as a lockable cut-out switch, a tagout device, and banana plug leads

- Insertion of faults to teach troubleshooting

- Cost-effective, high-quality solution

- Sturdy, mobile, two-sided workstation

- Designed according to CSA standards

- Contains advanced devices (PLC, AC Drive, PWM, DC Drive, Softstarter) and common electrical panel components

- Electrical connections between the modules mirror real-life connections

- The motors in the training system are actual industrial machines

- A simulation software allows students to complete all the exercises in the training system courseware on a computer without the need for any actual equipment

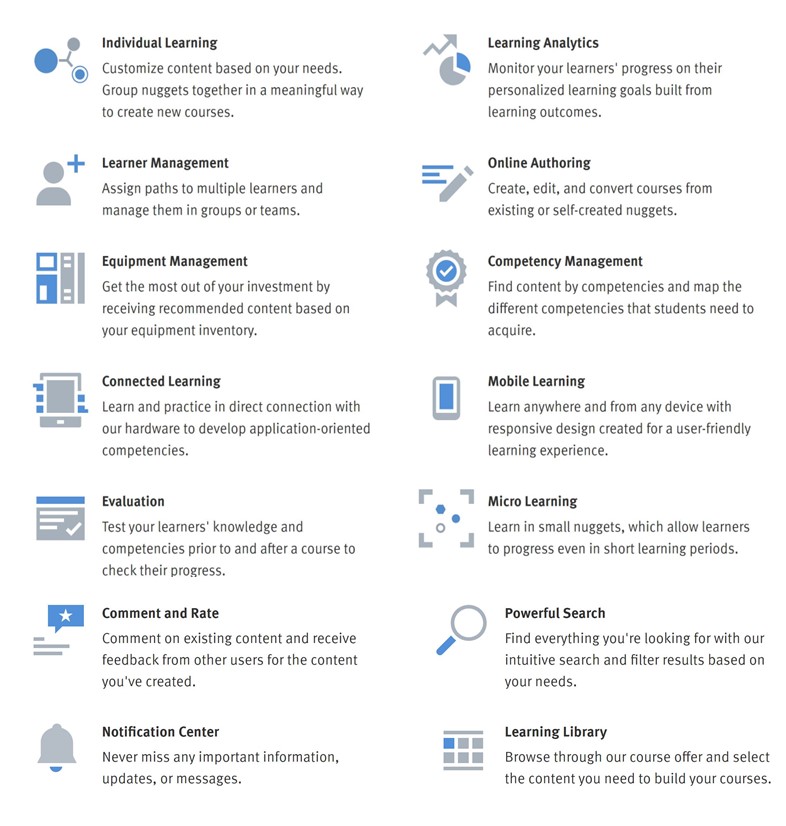

Festo LX – The online portal for teachers  and learners to access and create a customized learning experience.

and learners to access and create a customized learning experience.

Key features overview See what our learning portal can do: