THE FIRST HIGH-PERFORMANCE, ABRASIVE, WATERJET FOR MAKERSPACES

Made by OMAX, the easy-to-use waterjet machine cuts virtually any material. Now you can harness the power of waterjet technology, right in your lab or makerspace.

Advanced waterjet software coupled with 30,000 psi pump pressure drives the most efficient waterjet cutting tool for its size. Metal, glass, plastic, wood and more, the ProtoMAX cuts material up to 1-inch thick with a 12″x 12″ cutting area. Ideal for light commercial applications, DIY makerspaces, and educational institutions where cutting time matters.

Continually inspire your students to create. Teach the next generation, with next generation technology.

Request a Quote

As Seen at Education Labs in New England

Already familiar with the Protomax?

Great! Then you already know how versatile, intuitive to program, extremely flexible for digital fabrication applications and of course, safe this machine is — so why AET Labs?

- We specialize in technical education

- We have special education pricing and packages unavailable on the manufacturers site

- We make sure your site is prepped correctly

- We provide installation and commissioning

- We help integrate into your curriculum

- We provide custom ON-SITE training and professional development by our very own Applications Specialist

- We provide LOCAL technical support and maintenance programs by our own Field Service Technicians

CUTTING

- Cutting Area 12″ x 12″

- Max Material Thickness 1.00″

ACCURACY/SPEED

- Linear Positional Accuracy ±0.005″

- Repeatability ±0.003″

- Traverse Speed 100 inches per minute (IPM)

PUMP

- Pump Type 5 HP, Direct Drive

- Cutting Pressure 30,000 PSI

- High Pressure Water Flow Rate (.008″ Orifice) 0.22

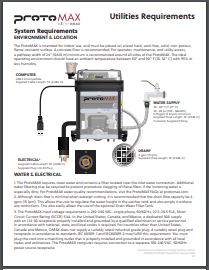

UTILITY REQUIREMENTS (WATER & ELECTRICAL)

- Electrical 240VAC / 60 Hz, 30 amp circuit; NEMA L14-30 Receptacle, 10′ cord

- Environment 50 to 90 °F (10-32 °C) ambient temperature with 95% or less humidity

- Location and Foundation Intended for use indoors; must be placed on a hard, level, solid, non-porous, flame resistant surface. A concrete floor is recommended.

WATER SUPPLY

- Minimum Input Water Pressure 45-85 PSI

- Minimum Flow Rate 0.75 GPM

- Temperature Required 45-80 °F

ABRASIVE

- Flow rate 0.25 lbs. per minute

- Recommended size 80 mesh

- Hopper Capacity 14 lbs.

CREATE PERSONAL DRAWINGS FROM  SCRATCH

SCRATCH

Designed exclusively for waterjet, our Intelli-MAX Proto software includes features you would expect from most CAD packages. In addition, it also features waterjet-specific tools, like cut quality and lead-in/lead-out, which help create the right part the first time.

EASILY USE DRAWINGS FROM OTHER CAD PROGRAMS

No need for additional 3rd-party software when using other CAD systems or drawings. Intelli-MAX LAYOUT supports files from other CAD programs including .dxf, .dwg, .ord, .ai, .pdf, and .svg formats. Importing into LAYOUT is one easy step.

NO CAD DRAWING, NO PROBLEM

Intelli-TRACE allows you to take personal images from your camera, the web, or just about anywhere else and convert them to a vector drawing. Built-in tools help you get your drawing ready to cut. Go from picture to part without additional software.

ProtoMAX wants to ensure your success right from the start! Even before you receive your ProtoMAX machine, you can prepare ahead. Start by downloading and reviewing the facility requirements document to ensure you’re ready for installation the day it arrives.

Essentials:

- PC with internet access

Recommended:

- Consumables bundle

- Support Plan

Basics:

- Intelli-Trace (2-4 hrs)

- Machine Set-up and Operations (2 hrs)

Advanced:

- Advanced Waterjet Cutting Applications (6 hrs)

The ProtoMAX is an excellent tool for teaching students about using abrasive waterjets for cutting applications. The powerful 5 hp direct drive pump delivers cutting speeds that provide a realistic, industrial quality experience and built in safety features will allow students more hands-on experience. The Intelli-MAX software is virtually the same as the versions that run OMAX industrial machines so when your students graduate to something larger, they’ll be ready.

However, since every curriculum is different our applications specialist can help provided some guidance to help craft a course that covers everything from how waterjet works to how to cut a part on the ProtoMAX.