In October 2023, the Massachusetts Vocational Technical Education Frameworks were updated to guide Chapter 74 state-approved programs on incorporating current business and industry standards, including how to utilize state-of-the-art equipment.

To help Massachusetts CTE educators choose the best equipment, we've gone through the advanced manufacturing framework and compiled a list of recommended industry-standard equipment, technology, and certifications that align with the framework.

Massachusetts CTE Framework: Advanced Manufacturing

Advanced manufacturing has become more complex in terms of the technical and digital skills needed to be proficient. The manufacturing industry is incorporating more automation and robotics into its processes to keep up with demand, improve outputs, and fill in labor shortages.

To meet the latest standards and skills, we recommend this list of equipment and certifications for Massachusetts Chapter 74 advanced manufacturing programs. These recommendations align with the Massachusetts Advanced Manufacturing framework, covering technical knowledge and skills.

Standard 3: Fundamentals of Design and Blueprint Reading and Standard 7: Computer Aided Manufacturing and CNC Programming

Fusion 360 or Onshape

Students quickly learn CAD and CAM principles with Autodesk Fusion 360 and OnShape, professional cloud-based CAD and CAM programs for learning technical drawing, 3D modeling, and blueprints related to CNC machines.

Stratasys Additive Manufacturing Certification Program

Stratasys industrial-grade 3D printers are accessible for students. The Stratasys Additive Manufacturing Certificate teaches students additive manufacturing technologies, design considerations from CAD to CAM, and more. The FDM Certification is accredited by NOCTI, providing students with a national industry-recognized certificate.

Standard 5: Machining Operations and Standard 6: Controlling Operations of Equipment

Techno CNC Plasma Tables and Routers

Techno CNC routers and plasma equipment make it easy for educators to prepare students for technical manufacturing jobs, available in multiple sizes and configurations.

Tormach CNC Machines

Tormach CNC mills and lathes are easier to learn and smaller than the more popular industrial CNC machines The Tormach CNC Certification Program gives students hands-on advanced manufacturing skills with a full-featured CNC controller. The program is accredited by NC3, giving students a national industry-recognized certificate.

Creaform 3D Scanners

Creaform 3D Scanners are designed for accuracy and dynamic referencing capabilities for reverse engineering and metrology applications.

Epilog Lasers

Epilog Lasers are high-quality engraving technology for CO2 and fiber metal marking applications.

Jet Metalworking Tools

Jet metalworking tools are high-quality and reliable power tools for students to use.

ProtoMAX Waterjet Cutter

Made by OMAX, this easy-to-use waterjet cutter cuts virtually any material: metal, glass, plastic, wood, and more.

Standard 8: Robotics in the Manufacturing Process

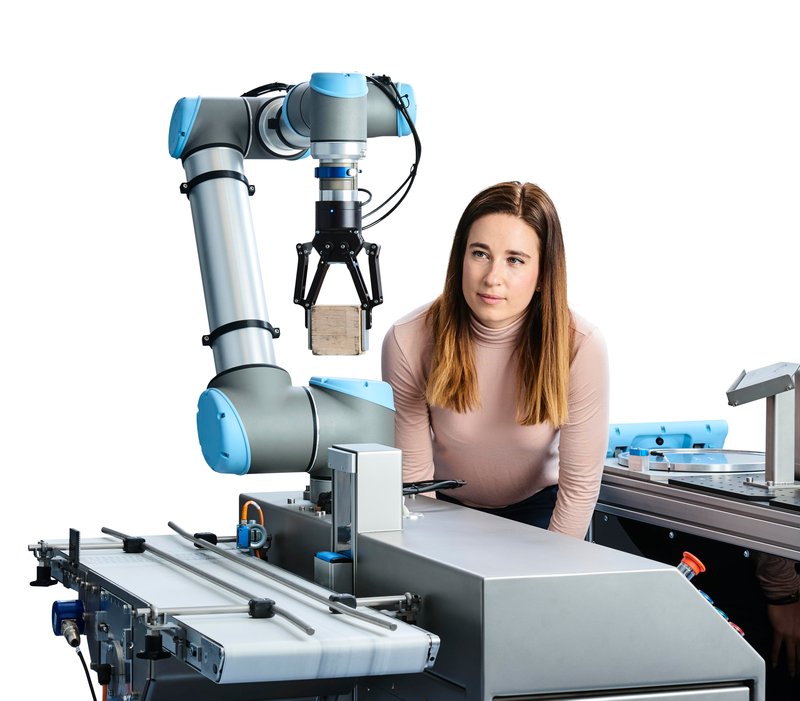

Universal Robots Skills Certification Program

With the Universal Robots Skills Certification Program, students gain an understanding of robotics and get a Universal Robots industry-recognized NC3 certification upon completion of hands-on training with a Universal Robots collaborative robot and 32 course credit hours of online learning.

Universal Robots Machine Tending Solution

Students learn about automated CNC machining and the use of robotics in the manufacturing process with the safe, easy-to-learn Universal Robots collaborative robot with dual Robotiq electric grippers. Connect it with your existing CNC machines, easily integrating with Tormach and HAAS Mini Mills and Lathes.

AET Labs specializes in helping CTE programs create and sustain their labs and shops. To make ensure you're using industry-standard equipment that aligns with the Massachusetts CTE Framework for Advanced Manufacturing, schedule a consultation with us. We provide all equipment and certifications recommended on this list, and we offer local service and professional development training for the instructors.