Collaborative robots are becoming increasingly important in the workforce, and educators are preparing their students by incorporating Universal Robots collaborative robots into the classroom. To learn about this, we interviewed Adam Zelny, Application Specialist at AET Labs, who works closely with instructors in New England to train them on how to best use technical equipment, like cobots, in the classroom.

Why do schools need to teach students about collaborative robots?

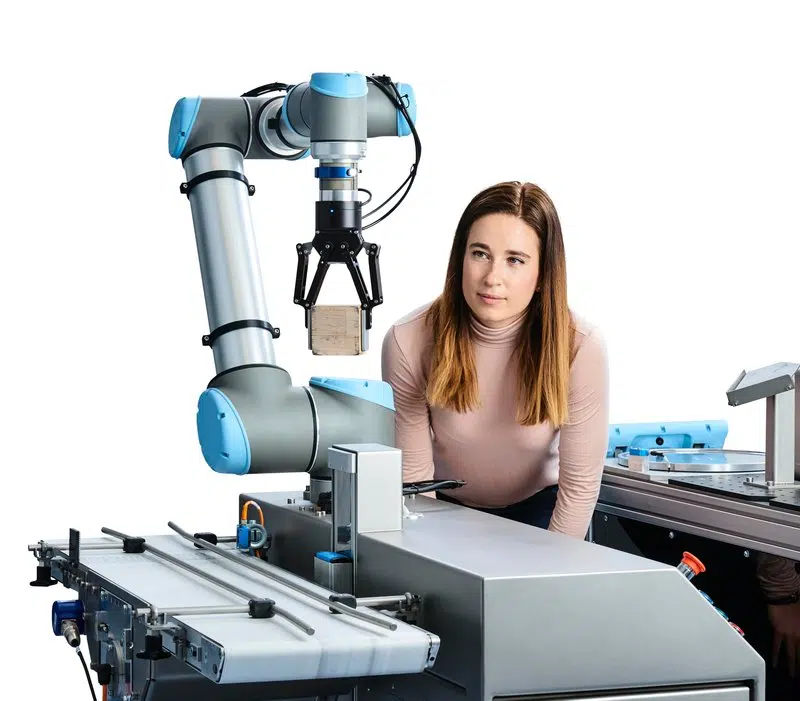

Collaborative robots (cobots) have become an integral component for organizations seeking to maximize precision and efficiency. They are employed in various industries: from sorting samples in lab environments to technical assembly for consumer products. Understanding how robots integrate into a business's productive environment also nurtures innovation, as it demands us to consider how to approach things beyond our immediate capacity.

Introducing these assets to students early on will aid their preparedness for their career-oriented pursuits down the road. On the other hand, I enjoy the thought of students drawn toward art and design learning about these machines. I feel many schools seek ways for their departments to overlap, and I often engage with teachers on this topic.

What skills do students learn from collaborative robots that are different from what they learn from traditional industrial robots?

While a traditional robot's goal may be to work autonomously, with minimal tending from a human user, a cobot is designed to work in tandem with its user. This approach is ideal for learning precisely how a robot functions, as programming and monitoring the robot are integral parts of learning its abilities.

Perhaps above all else, students are constantly challenged in problem-solving situations with nearly infinite room for improvement. Since we are working with these machines together, it also invites collaborative feedback from fellow students and instructors that benefit project goals.

How do collaborative robots prepare students for jobs in industrial automation?

Because cobots do not need machine guarding and are easier to program than traditional industrial robots, they can quickly be deployed for various other jobs than initially intended.

For instance, a small shop may need to use the cobot for a machine tending application but afterward may need to test each piece's quality. With a quick change of the program, the cobot can check for tolerances, and data can be used for statistical analysis. Need to do some light assembly work? How about a packaging application? The cobot can be moved to a table or the loading dock with a mobile base. The applications are endless.

Additionally, since the cobot can be used for so many more applications, the investment can be justified to a much greater extent. Now, can you imagine the industry-relevant applications students will come up with?

How are instructors incorporating collaborative robots into their teaching?

At the high school level, I have seen instructors begin by introducing basic pick-and-place commands to their students, which is a great way to demonstrate the programming interface. That only scratches the surface: beyond basic movement controls lies a huge world of logic-based programming. Computer Science teachers are finding an entirely new platform in working with collaborative robots!

I visited a high school recently and found their UR5 with a pencil in its gripper. The instructor showed his students some simple applications by having the robot draw some symbols.

What other equipment would you recommend students use alongside collaborative robots?

When I think about makerspace and tech-lab environments, there is no limit to how collaborative robots can interact. Incorporating cobots with learning systems like Festo's Meclab is an excellent way to onboard students with specific automation workflows.

On the other hand, I think about how those basic pick-and-place programs might be used alongside high-volume production with tools like laser cutters and CNC routers. A Robotiq vacuum gripper would fit perfectly into this application.

I will also loop back to art again, as I think there has always been a barrier between engineering and art departments in high schools. Imagine how art teachers might employ a cobot in the classroom.