Learning the Fundamentals of Mechatronics with the Festo MecLab®

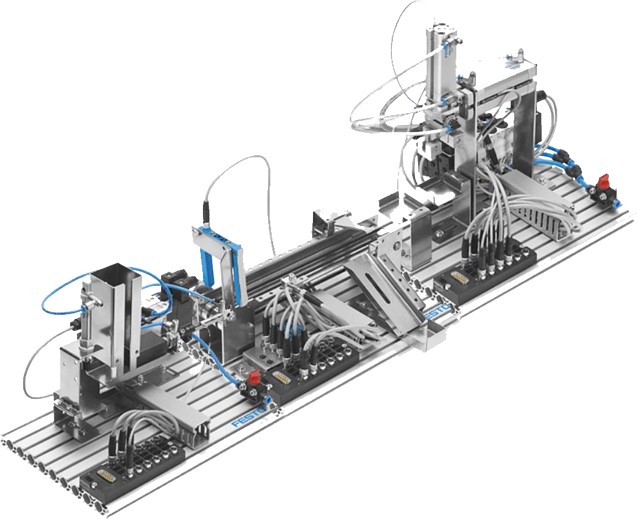

The purpose of MecLab® is to provide students an opportunity to learn the practical and theoretical aspects of automation technology. It consists of three separate systems that can be used in combination or as stand-alone stations, sparking student interest in scientific thinking. MecLab® helps students gain insight into one of the most significant fields of application for automation technology – production technology.

With an open architecture design, the Festo MecLab® can be combined with other technologies including PLC’s, sensors and even Cobots!

Request a Quote

What can you do with a Meclab?

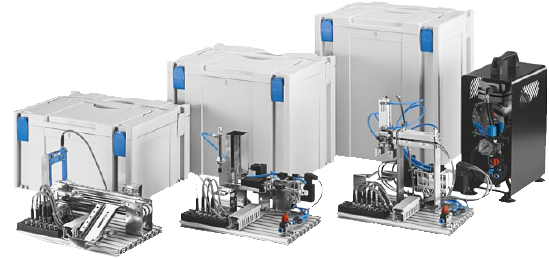

Contains everything you need for working with MecLab®:

- 1 Stacking Magazine station

- 1 Conveyor station

- 1 Handling station

- 1 compressor

- 3 x EasyPort to connect the stations

to the computer - 3 x power supply unit with connector

- FluidSIM®

- Documents on CD-ROM

- Workpieces

- Tools

- Screw set

- Systainers

With MecLab® a wealth of teaching topics and curriculum requirements can be covered, because its contents can be adapted accordingly:

- Introduction to industrial production

- Using technical terms correctly

- Planning, developing and setting up technical systems

- Understanding and using technical documentation; creating and using schematic diagrams, circuit diagrams, parts lists and technical drawings

- Building models and creating simulations

Understanding and applying open and closed-control loop systems - System thinking and understanding the interactions of subsystems

- Developing and constructing electric, electronic and pneumatic circuits

- Understanding and using pneumatic and electrical actuators, sensors and controllers

- Using computers as tools for programming and simulation

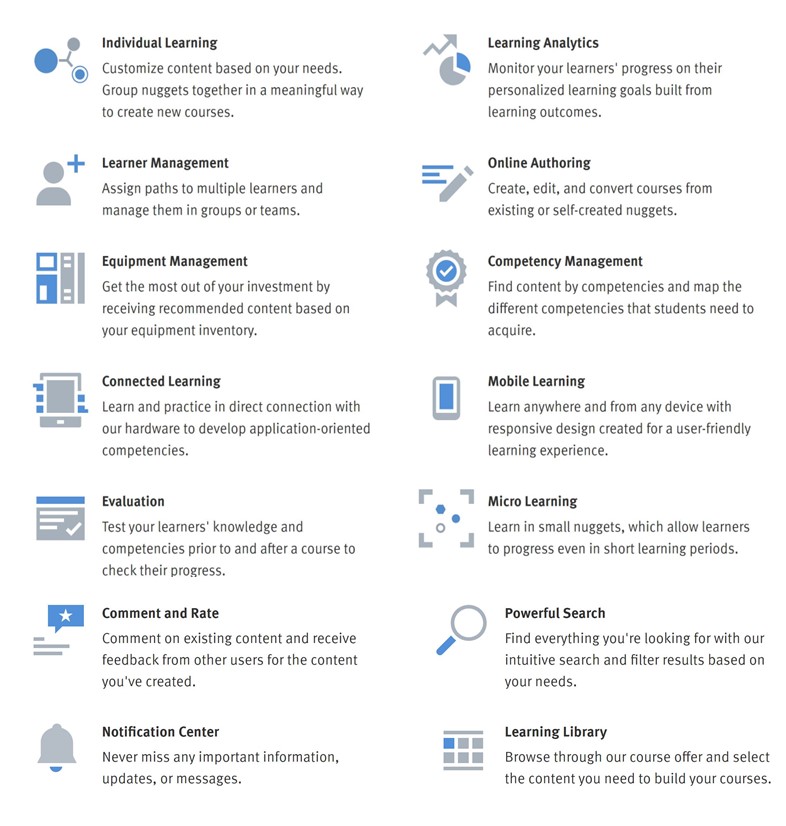

Festo LX – The online portal for teachers  and learners to access and create a customized learning experience.

and learners to access and create a customized learning experience.

Key features overview See what our learning portal can do: