UNCOMPROMISING PERFORMANCE

Introducing the new Epilog Fusion Pro. 5G acceleration and 165 IPS engraving speeds provide the fastest engraving in the industry. And the IRIS™ Camera Positioning system allows you to precisely place your artwork on screen in seconds.

- Fusion Pro 24: 24” x 24” x 9″ (610 x 610 x 228 mm) work area

- Fusion Pro 36: 36” x 24” x 9″ (914 x 610 x 228 mm) work area

- Fusion Pro 48: 48” x 36” (1219 x 914 mm) work area

- Wattages:

- CO2: 50, 60, 80, or 120 watts

- Fiber: 30 or 50 watts

- Dual: Configure your laser with both CO2 and Fiber sources

As Seen at Education Labs in New England

The Fusion Pro laser Epilog’s newest laser machine delivers our fastest speeds, largest work area, and highest engraving quality yet, along with a brand-new state-of-the-art camera system.

The Fusion Pro laser engraving and cutting machines from Epilog are our top-of-the-line laser systems and combine a large work area with the latest technological features.

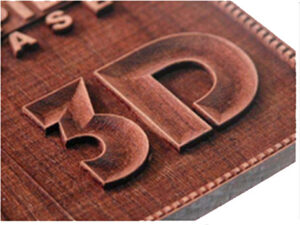

CO2 Material Compatibility

| Engrave | Cut | |

|---|---|---|

| Wood | x | x |

| Acrylic | x | x |

| Fabric | x | x |

| Glass | x | |

| Coated Metals | x | |

| Ceramic | x | |

| Delrin | x | x |

| Cloth | x | x |

| Leather | x | x |

| Marble | x | |

| Matte Board | x | x |

| Melamine | x | x |

| Mother of Pearl | x | x |

| Paper | x | x |

| Mylar | x | x |

| Pressboard | x | x |

| Rubber | x | x |

| Wood Veneer | x | x |

| Fiberglass | x | x |

| Painted Metals | x | |

| Tile | x | |

| Plastic | x | x |

| Cork | x | x |

| Corian | x | x |

| Anodized Aluminum | x | |

| Stainless Steel | * | |

| Brass | * | |

| Titanium | * | |

| Bare Metals | * | |

| * CO2 lasers will mark bare metals when coated with a metal marking solution. For more information, visit our laser metal marking page. | ||

Laser Dashboard and Job Manager

The Laser Dashboard™ controls your laser’s settings from a wide range of software packages – from design programs to spreadsheet applications to CAD drawing packages. As the interface to the laser, the Laser Dashboard makes the features you use most often accessible at the touch of a button.

The Job Manager is a powerful tool that will allow you to access any job you have sent to the laser, view the settings you used on any past job, re-run projects, access your material database, and much more.

Epilog laser systems work through a print driver, so you can design your files in many different graphic software packages including Illustrator, Photoshop, AutoCAD, and much more. However AET Labs recommends and supports CorelDraw, which is the most commonly used software

Essentials:

- PC

- Building exhaust or fume extraction system

- Graphics Software (CorelDraw or equivalent)

- Consumables

Recommended:

- Rotary attachment

- Vector cutting grid

- Photo laser plus software

Basics:

- Laser Dashboard and Job Manager (1-2 hrs)

- Laser set-up and Operations (~1-2 hrs)

- Using CorelDraw with your laser (4-6 hrs)

Advanced:

- Advanced laser applications (4-6 hrs)

For applications and project ideas:

- AET Labs custom lesson plan