Overview

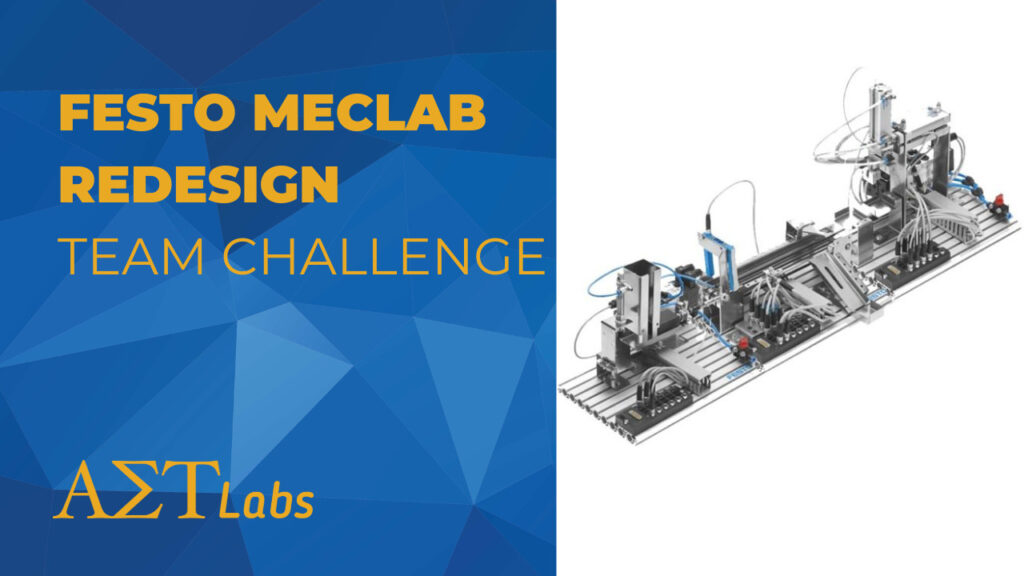

Mechatronics is the combination of electromechanical systems, CAD, and computer programming. The Festo MecLab system is an excellent representation of this industry that challenges students to learn the technologies and develop skills to be future automation technicians and engineers.

Challenge Objective

Redesign a Festo MecLab system that will dispense marbles into a black or metallic container, which will be ejected from the system to a collection platform.

Who Should Participate?

Students from engineering or robotics programs that have Festo MecLab systems. Must be students at a New England high school.

Challenge Details

Hardware Allowed

- One standard Festo MecLab set (stacker, conveyor, pick/place) and expansion kit

- 3D-printed parts, fixtures, and assemblies

- Programmable Logic Controllers (PLC) or other control system

Required Operation

- Teams must demonstrate a minimum of three successful cycles without any manual assistance

- One cycle should include the operation of three independently activated, intermixed (black, metallic) containers

- One operation should include one independently dispensed container activated by means of a push button

- Push 1x = 1 marble

- Push 2x = 2 marbles

- Push 3x = 3 marbles

- End of operation should include a collection platform capable of holding three fulfilled orders

- An indicator light will flash, notifying the operator that the platform is full

- The system will not be able to activate another operation until the platform is cleared

Judging

- Teams was be judged on:

- Successful operation of three complete cycles (points will be deducted for any manual intervention or failed operations)

- Creative use of 3D printing with MecLab components and operation

- Appearance: wiring is neatly organized, printed parts robustly designed with smooth features

Prizes

The top 3 teams won a gift certificate:

- 1st place: $300

- 2nd place: $200

- 3rd place: $100