Overview

Mechatronics engineers create and improve automated processes and are sometimes tasked to create simple, cost-effective, and dependable automated processes to replace tasks that are currently being implemented manually. They research, design, implement, and maintain intelligent processes by applying mechanical, electronic, computer, and software technologies.

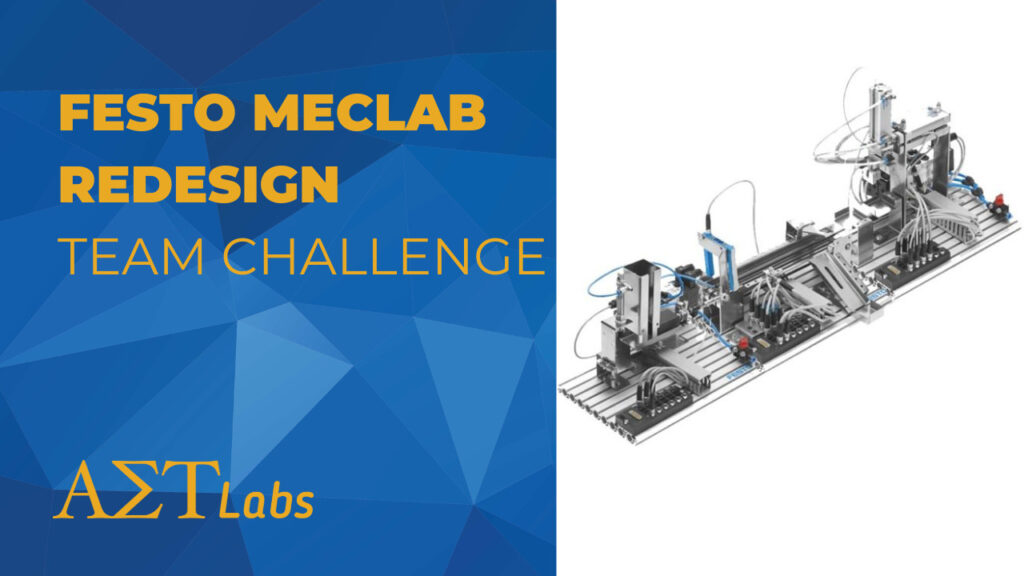

By using the Festo MecLab System, students learn the technologies used in the industry and develop skills to be future automation technicians and engineers.

Challenge Objective

Redesign a Festo MecLab system to dispense marbles into a container that incorporates an automated metrology process for sorting.

Who Should Participate?

Students from engineering or robotics programs that have Festo MecLab systems. Must be students at a New England high school.

Challenge Details

Hardware Allowed

- Must utilize as many components and hardware as possible from a standard Festo MecLab kit (stacker, conveyor, pick/place) and expansion set.

- Black or Chrome containers from the MecLab kit will be used for holding standard marbles

- The entire footprint should be limited (as close as possible) to 3 aluminum extrusion base panels from the MecLab kit.

- Demonstrate the use of 3D printing for custom designs of fixtures and assemblies.

- Demonstrate the use of Programmable Logic Controllers (PLC) or other mini control systems.

- The project may require additional air cylinders, valves, sensors, and other components outside of the standard Meclab Kit. These items can be purchased directly by going to www.festo.com as well as other sales channels. Festo Automation components are preferred for their quality and reliability, but other brands will be acceptable.

Required Operation

Teams must demonstrate a fully automated operation to do the following:

- A stacking magazine station will release one container by pressing a start button

- A dispensing station will fulfill an order with 3 or 6 marbles

- A metrology station will test and confirm that a quantity of 3 or 6 marbles are dispensed into each container.

- When a quantity of 3 marbles has been detected, a light will illuminate solid for 5 seconds, and the container will be transported to a collection area marked "Product 1."

- When a quantity of 6 marbles is detected, a light will flash intermittently for 7 seconds, and the container will be transported to a collection area marked "Product 2."

- One operation should include one independently dispensed container activated by means of a push button:

- Push 1x = 3 marbles

- Push 2x = 6 marbles

- The end of each operation should include a collection platform capable of holding two properly fulfilled orders.

Judging

Teams will be judged on:

- Successful operation of two complete fulfillments (points will be deducted for any manual intervention or failed operations).

- Creative use of 3D printing with MecLab components and operation.

- Appearance: wiring is neatly organized, printed parts robustly designed with smooth features.

Prizes

The top 3 teams will win a gift certificate:

- 1st place: $500

- 2nd place: $300

- 3rd place: $200

Congrats to the Winning Team!

The Beep Boop Troop from Bristol-Plymouth Regional Technical High School in Massachusetts won. Here is their submission: