Mechatronics integrates mechanical, electrical, and software components to create smart, automated systems that perform complex tasks, leveraging advanced technologies, such as sensors, microcontrollers, and computer programming. It's a field rapidly changing New England companies in the life sciences, manufacturing, and defense industries. Companies use automation to increase production and improve precision and intelligence. Jobs like mechatronics engineers and automation technicians are needed to run these systems, which are in demand in New England.

For high schools in New England, teaching students valuable mechatronics skills prepares them for a field that will grow for years from now, giving them a competitive edge in the job market. Mechatronics can be intimidating and ambiguous for students to understand, so giving them hands-on experience through mechantronics kits is an effective way for students to learn.

Mechatronics at Montachusetts Tech

Dean Lepkowski, an Engineering Technology Teacher at Montachusett Regional Vocational Technical School, is teaching his students mechatronics. Dean has been in the electrical controls and automation field for many years. He worked on industrial automation systems as a technician and has been teaching robotics and automation for almost 20 years.

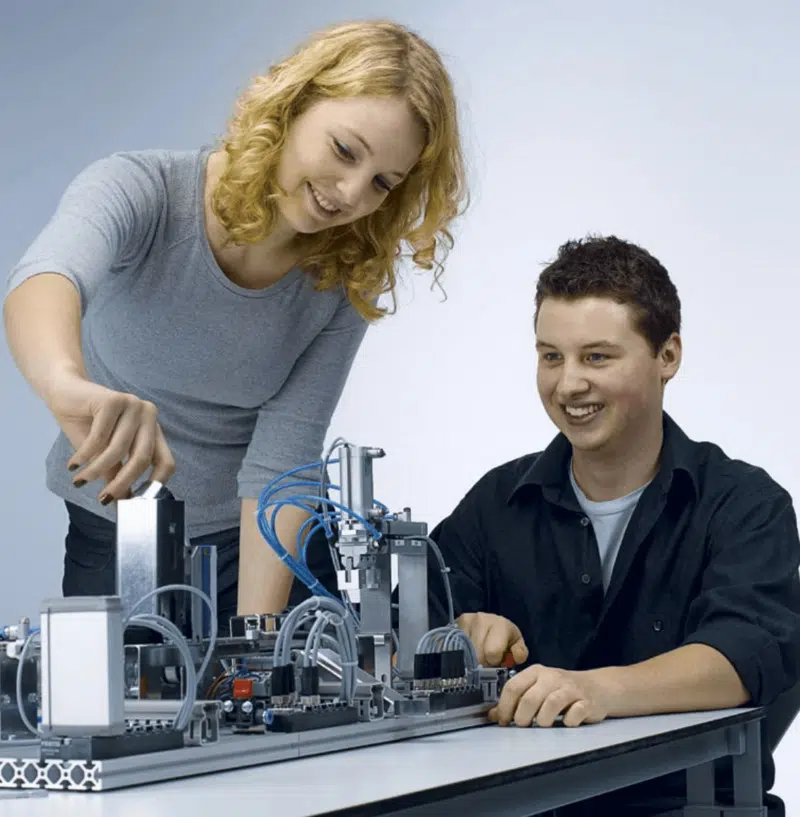

Teaching mechatronics allows his student to see all areas of engineering in one place at the same time. Students don't typically get excited about one area of a working piece of equipment—they like to see it working together. For example, students love cars, not just the dashboard or the braking system. Once they see the actual machine, then they can dissect it. Dean has been teaching in three different areas in his 20-year career: Robotics and Automation, Electrical, and Engineering. The students that have been the most excited are the ones who have physically designed, built, wired, and programmed different types of equipment. This is the only time when students have asked to take pictures or video recordings of their work in his 20 years of teaching. Seeing students proud of their work and fist-pumping, high-fiving, and wanting to show others their accomplishments is the most rewarding part of teaching.

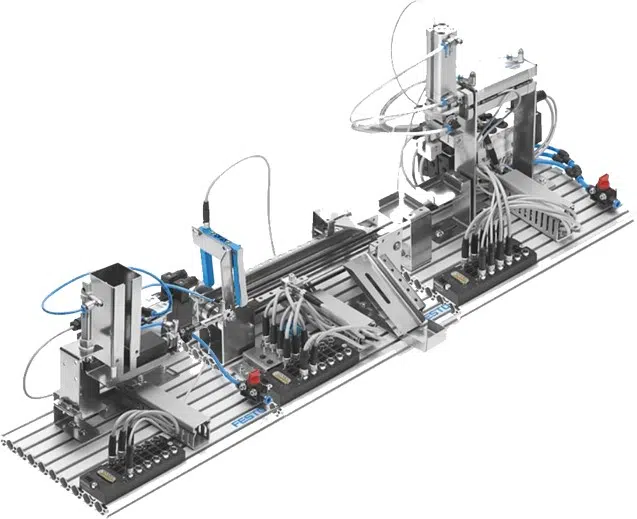

Dean uses the Festo MecLab® system to enhance his student's skills in PLC programming. He does this by first having students learn conventional relay ladder logic and then converting that to simulated PLC control wiring. Once they can convert ladder control wiring to PLC programming, then they move on to the Festo MecLab. They break the MecLab into its individual stations and hardwire controls to the cable using the 25-pin connector. This allows each student to understand the station that was tasked to them. They then rotate the stations until all students have used the stations. The next step is to join all stations together to create a larger automated process. This leads to students designing and creating larger projects going forward.

What are Mechatronics Kits?

Mechatronics kits, like popular robotics kits, come with components for students to build a variety of automated systems. They enhance learning for students and improve their understanding of complex concepts.

How to Choose the Best Mechatronics Kits

The best mechatronics kits prepare students by exposing them to equipment used in the industry. For example, Festo is a leading manufacturer of automation technology used by companies in New England and around the world. They have an education division, Festo Didactic, that offers schools the same technology used in companies for students to learn from. The Festo MecLab is a mechatronics kit they designed for schools.

The best mechatronics kits also provide teaching resources for instructors. Teachers at all knowledge levels should feel confident in teaching mechatronics concepts. Mechatronics kits that come with curriculum, project ideas, and training help educators teach their students mechatronics.

Mechatronics Kits from Festo MecLab

The Festo MecLab system allows students to learn the practical and theoretical aspects of automation technology. It consists of three separate mechatronics kits that can be used in combination or as stand-alone stations, sparking student interest in scientific thinking and knowledge of automation technology. With an open architecture design, the Festo MecLab can be combined with other technologies, including PLC's, sensors, and even collaborative robots!

The Festo MecLab comes with teaching topics and curriculm to help educators teach systems thinking and the technical aspects of automation technology. In addition, AET Labs provides personalized in-person training to customize how educators can incorporate the Festo MecLab into their program.

Combining the Festo MecLab with the Festo Industry 4.0 Certification Program (FICP) provides students with an even more relevant experience. The FICP is a multi-level pathway involving high schools, post-secondary institutions, and the industry, all facilitated by NC3. The Introduction to Mechatronics course in the certification program uses the Festo MecLab, which helps to prepare students for the certification test. Passing the test means they earn an industry-recognized credential in mechatronics!

Automation is a critical component to many New England companies. Students who use mechatronics kits and earn credentials get engaged and learn about an exciting career path.

If you're interested in learning more about how to bring mechatronics kits to your program, are participating in a future Skills USA Mechatronics competition, or are an existing Festo MecLab customer, please get in touch with AET Labs. We are the only company in New England offering Festo equipment and training to educators.