Training Students for Mechatronics Jobs

Mechatronics is an exciting field for your engineering students who enjoy critical thinking, problem-solving, and hands-on work. Manufacturing and production facilities need mechatronics and automation engineers who develop and maintain complex integrated automation systems. As an educator, you can help companies local to you by training students with specific skills and technologies in your mechatronics lab.

We compiled job descriptions from companies in New England hiring for mechatronics roles. We put together a list of skills they are looking for to help you understand how to best train students in your mechatronics labs. Companies looking for mechatronics employees come from a range of industries, including life sciences, manufacturing, and defense:

- Siemens Healthineers in Massachusetts

- Biogen in Massachusetts

- RBC Bearings in Connecticut

- General Dynamics Electric Boat in Rhode Island

- Celestica in New Hampshire

Working in mechatronics involves understanding the synergistic combination of mechanical engineering, electrical engineering, electronics, information technology, and systems thinking utilized in the design of products and automation processes. Students need to understand mechatronics concepts and get hands-on experience using mechatronics tools and equipment with mechatronics certifications.

Take a look at the list below. Are you teaching your students these concepts?

Companies are seeking mechatronics employees who have knowledge in these areas:

- Sensors, actuators, cabling

- Servo systems

- Motion control systems

- Robotic system integration

- Electromechanics

- Precision mechanics and pneumatics

- Mechanical and electrical design practices

- Industrial manufacturing processes

- Electrical and robotics safety systems

- Liquid handler instruments and lab automation platforms

In many mechatronics roles, employees are expected to have hands-on experience with specific technologies, including:

- PLC/industrial controllers

- Programming industrial/collaborative robots

- 2D/3D design with software

- CNC manufacturing equipment

- Industrial cutting, welding, coatings, automation or robotics

To give your students the experiences they will need for mechatronics jobs, you can incorporate mechatronics certifications into your lab using mechatronics equipment and tools. From industry-relevant equipment to industry-recognized certification programs and student competitions, your students can get a head start on their future mechatronics, automation, and robotics careers.

Here are some mechatronics certifications using mechatronics equipment and tools to explore:

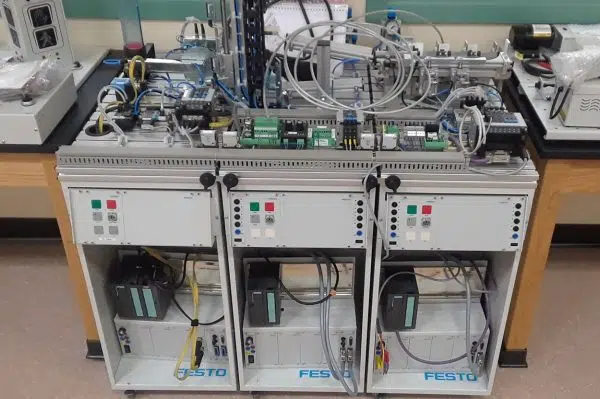

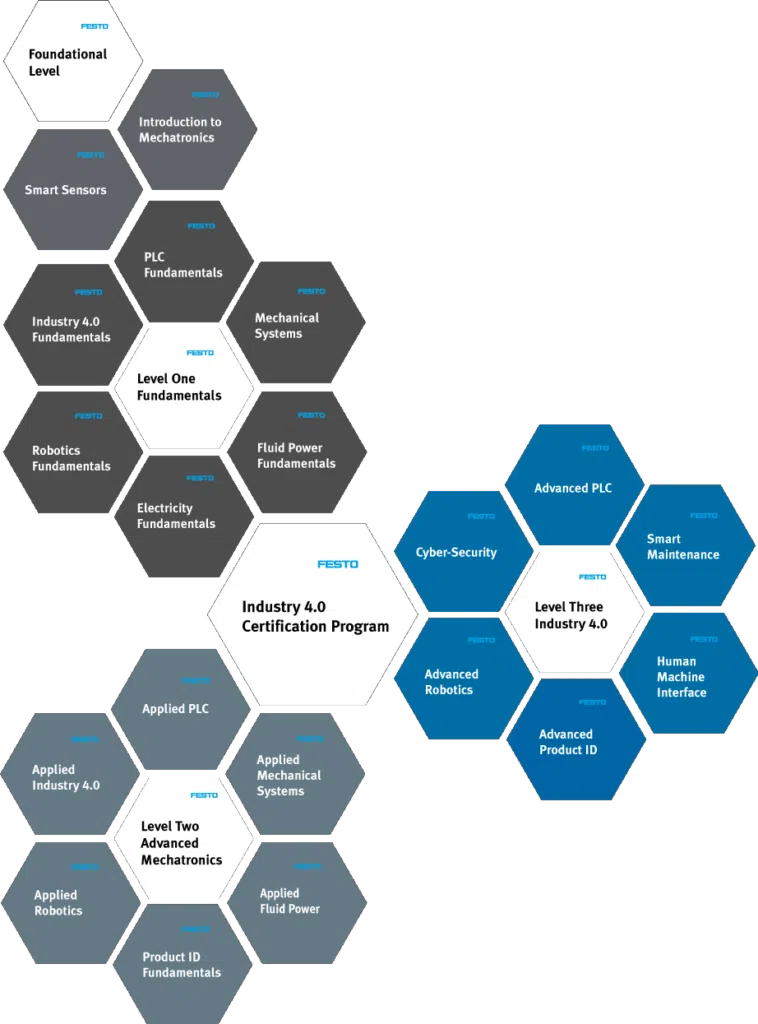

The Festo Industry 4.0 Certification is an NC3 accredited comprehensive program for high schools, community colleges, and universities to provide industry-recognized training to students to teach them Industry 4.0 and mechatronics skills, including:

- Intro to Mechatronics Training System

- Programmable Logic Controllers and Industrial Networks

- Pneumatics and Hydraulics

- Mechanical Systems

- AC and DC Electricity

- Industrial Controls and Sensors

- Robotics

- Smart Sensors

- Cyber-Physical Production System

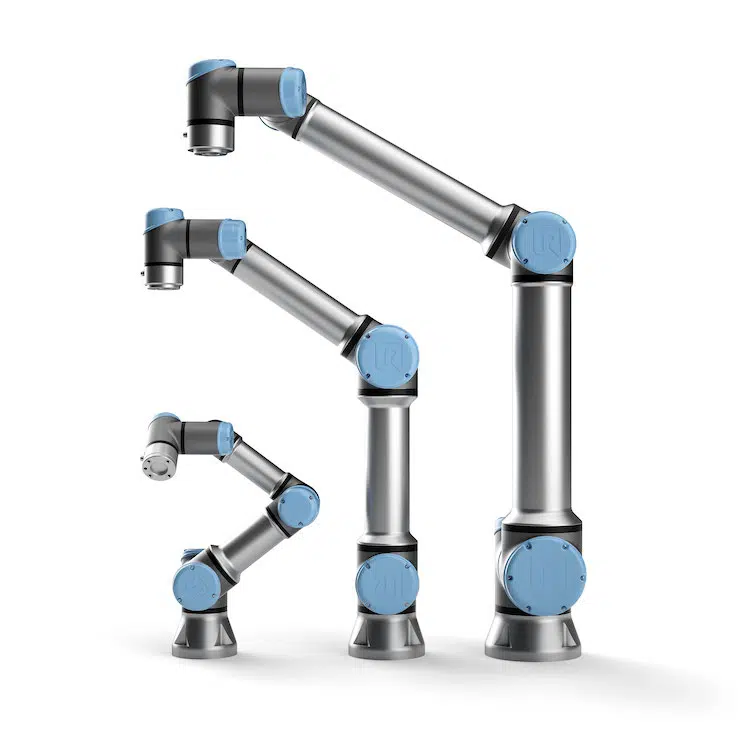

Universal Robots are collaborative robots used in the industry to improve production with intuitive and user-friendly programming that your students will quickly pick up. The Universal Robots Skills Certification Program is a fully integrated program developed specifically for education. It comes with a Universal Robots collaborative robot, hardware and software, a 4-day teacher certification training program, and 24 course licenses for students to learn:

1. Complete E-Learning

2. Safety

3. Intro to Robotics

4. The Robotics World

5. Getting Started

6. Operations And Motion

7. Programming

8. Palletizing

9. Features/Planes

10. Safety Settings

Additional 1-on-1 on-site instructor training is also available through AET Labs.

The Kuka ready2_educate industrial robot certification program was designed specifically for educational institutions to teach students the programming and operation of modern industrial robots. The Kuka ready2_educate modular training cell incorporates the KR 3 AGILUS small robot and service-proven KR C4 compact controller – while also being equipped and preconfigured for special didactic applications.

zSpace is the leader in augmented reality education for a range of applications, including mechatronics. Their immersive learning platform engages students while giving them hands-on training with valuable industry-relevant advanced manufacturing skills. The zSpace introduction to mechatronics program is aligned to NOCTI certification requirements, so students can earn industry credentials.

Skills USA includes a mechatronics competition that your students can join. AET Labs is honored to lead the Massachusetts Skills USA mechatronics program and proud of Blackstone Valley Technical Regional High School for winning the gold in the 2022 competition!

Mechatronics is an important field and career path in New England, involving theoretical knowledge and hands-on work. AET Labs provides mechatronics certifications using mechatronics equipment and tools to help train your students, from high school to undergraduate programs. Contact us to find out how to support your mechatronics lab!