Demand for robotics technicians is growing as technology evolves and the need for quicker, more accurate outputs increases. To prepare job candidates for filling such positions, New England schools are providing opportunities for relevant training and hands-on experience. The Northeast Advanced Manufacturing Consortium (NAMC) created a two-year robotics apprenticeship program that trains the next generation of robotic technicians through Greater Lawrence Technical School and Northern Essex Community College.

High Demand for Robotics Jobs in Massachusetts

Robotics jobs are rising in sectors like manufacturing, healthcare, biopharma, and life sciences. In Massachusetts, more than 400 companies now produce various robotic systems, contributing to the local robotics and automation ecosystem.

Nationally, US corporations spent $25.2 billion on such devices in 2023. The future is bright: The market is set to reach $152.9 billion in 2033, a robust Compound Annual Growth Rate of 19.8%.

Employees Gain Hands-on Robotics Experience in Massachusetts

Robotics is a rapidly evolving, highly innovative field that requires skilled technicians to maintain, run, and troubleshoot automated systems. Massachusetts technical high schools, community colleges, and universities offering robotics and automation training options help fulfill local employer demands and keep employees up-to-date with the industry’s latest technologies, tools, and techniques.

To help employers upskill their current workforce and retain employees, NAMC partnered with Greater Lawrence Technical School and Northern Essex Community College to create a new two-year robotics apprenticeship program. Industry leaders, workforce boards, and educators collaborated to create the program, which teaches participants important skills to enhance operational efficiency using robots. The apprenticeship garnered support from government and manufacturing industry consortiums and is a Registered Apprenticeship Program with the Massachusetts Division of Apprenticeship Standards.

The program stresses the practical and not just the theoretical. Its structured, hands-on training combines on-the-job learning with classroom instruction. Students spend 300 hours working with industry-leading robotics, mechatronics, and automation equipment. In year one, training takes place at Greater Lawrence Tech and Northern Essex Community College during year two, all in the evenings. In addition, each apprentice will have 2,000 hours each year of on-the-job training. Participants will gain valuable skills and experience, making them highly qualified to meet the demands of the modern robotics workplace.

Apprenticeship Benefits

The robotics apprenticeship program will help employers train employees cost-effectively. With access to certified and experienced technicians trained through the program, employers will benefit from a workforce that knows how to use the latest robotics technologies and is informed of industry standards to help them with their future automated production needs. The apprenticeship program will also help with employee retention by investing in their professional skill development.

Training With Leading Edge Robotics Equipment

AET Labs provided some of the training equipment that will be used in the hands-on classroom training. The equipment used in the classroom is the same equipment used by companies; therefore, when the program is complete, apprentices will be ready to step into a full-time position and be productive on their first day at the job. Equipment used in the robotics apprenticeship program includes:

Universal Robots Collaborative Robots

Universal Robots collaborative robots work alongside humans and perform tasks like assembly, welding, painting, packaging, and machine tending. These systems feature flexibility and are designed to be safe to work alongside. No programming experience is needed to get started. The robots are used by large enterprises and small and medium-sized businesses.

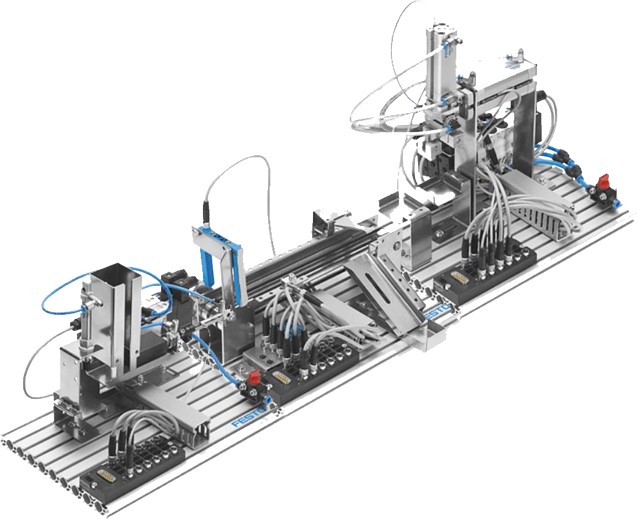

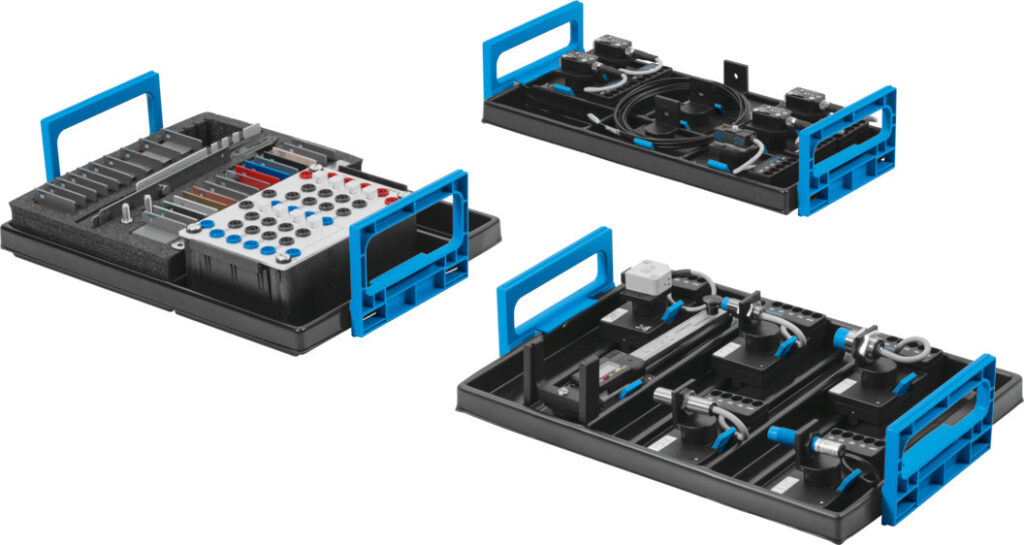

Festo MecLab Training System

With the Festo MecLab Training System, apprentices will gain experience in mechatronics. They will learn to apply mechanical, electrical, computer science, and control engineering principles to design, develop, build, and deliver robotic systems that automate traditionally manual processes.

Festo Electropneumatic Training System

Electropneumatics combines the strength of pneumatic systems with the precision and programmability of electrical control. In robotics, they can be used to power robotic arms and machines with precise control over movement.

Festo Sensor Training System

Sensors are special-purpose devices that detect and respond to the physical environment. They measure items like light, heat, motion, moisture, and pressure, which robots use to control actions, adjust movements, and make decisions in real time.

Robotics is a growing field in Massachusetts. New England educational institutions that offer programs like the new robotics apprenticeship program will help employers and employees contribute to the local economy.

AET Labs provides turnkey services to educational institutions in New England developing career training and workforce development programs. We are a partner in helping to identify equipment that best meets the needs of programs in addition to offering local installation and training for instructors. AET Labs is the area’s leading expert in finding the right equipment to train students in robotics and automation programs. Contact us to learn more!