Designed for Education and Makers

The xsTECH Pro supports probing and 4th-axis machining, making it ideal for classrooms and makerspaces. Basic tool holding, workholding, and a carbide endmill kit come standard, with optional accessories available for advanced projects. With PathPilot’s intuitive interface, students can learn hands-on machining, tool changing, and probing in a controlled, scalable environment. Whether you’re teaching fundamentals or building real prototypes, the xsTECH Pro makes professional CNC more accessible than ever.

- 4-station automatic tool changer

- Full enclosure for enhanced safety

- Runs on single-phase power

- Cuts wood, plastics, and aluminum

- Optional machine tending add-on capabilities

- Safety certifications: UL,CE

A Versatile Desktop CNC Router for Beginners and Pros

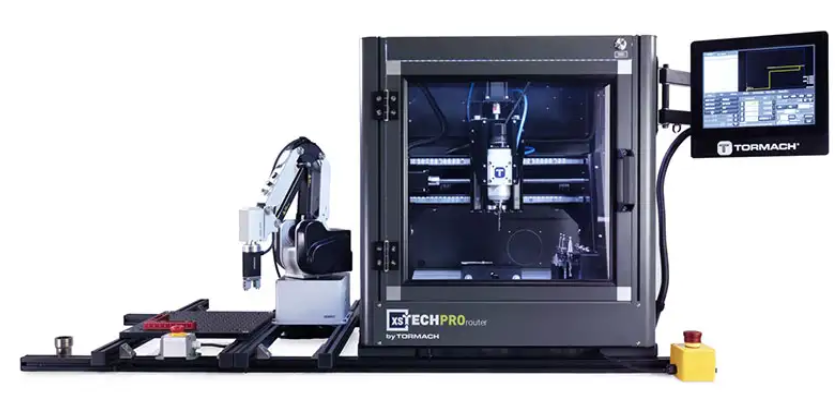

The xsTECH Pro is a fully assembled, desktop CNC milling machine built for classrooms, prototyping, and specialty manufacturing. It fits on a standard 24-inch countertop and includes a 4-station automatic tool changer, full safety enclosure, and high-speed spindle capable of 20,000 RPM. Designed to cut plastics, wood, and aluminum, it’s equipped with linear guides and ballscrews on all axes for improved precision and repeatability.

A Desktop Router Ready for Automation

The xsTECH Pro isn’t just a compact CNC router; it’s designed with automation and integration in mind. It can be incorporated into automated work cells for lights-out manufacturing, educational robotics projects, or advanced prototyping environments. Its 4-station automatic tool changer and optional probing system allow for fully automated workflows, while the enclosed design ensures safety in unattended or collaborative setups. Whether you’re developing a training cell or building out a robotic production line, the xsTECH Pro brings industrial CNC automation capability to the desktop.

Why The xsTech Pro is Ideal for Educators

- 4-station automatic tool changer – Run multi-step operations without manual tool changes, streamlining workflow and reducing classroom downtime.

- Full safety enclosure – Wide windows on three sides with bright task lighting, keeping students safe while allowing for group instruction.

- PathPilot control system – Intuitive interface with touchscreen, Wi-Fi, and PathPilot Hub integration for file transfers and simulation.

- Automation ready – Optional cobot integration for Industry 4.0 instruction.

- Compact footprint – Fits on a 24 inch countertop and weighs only 150 lbs.

- High-speed ISO 10 spindle – 20,000 RPM spindle with ER11 collets for precision cutting in wood, plastics, and aluminum.

- Ballscrews and linear guides – On all axes for accuracy and repeatability in every cut.

- Educational flexibility – Supports probing, 4th axis machining, and expandable accessories for advanced training projects.