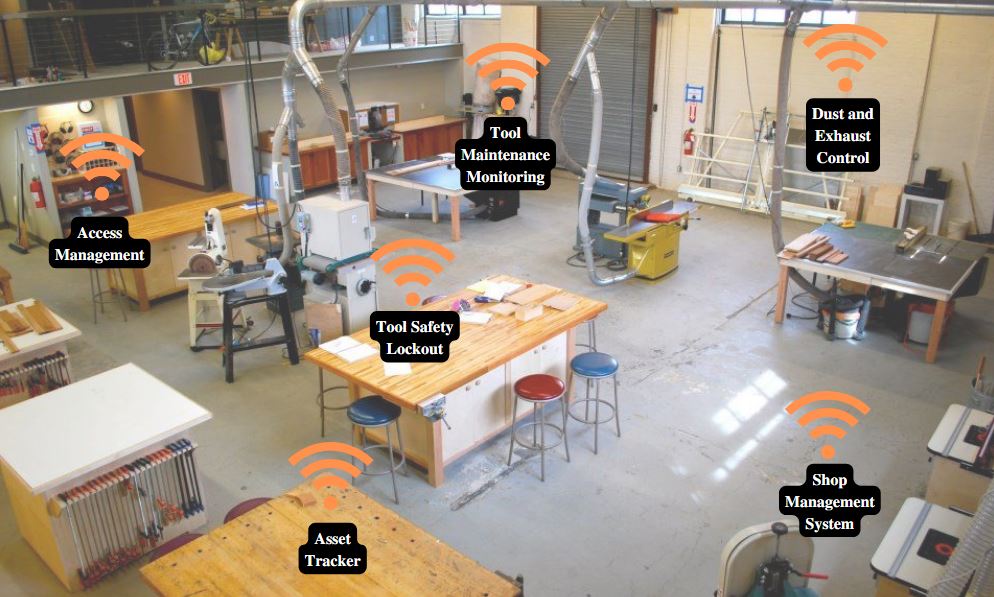

Take Control Of Your Workshop

GRIT is a wireless automation platform for workshops. The system is flexible and scalable to satisfy the diverse range of machinery that are found in woodshops, metal shops, and makerspaces. System features include:

- Access Management

- Tool asset tracker

- Tool safety lock-out

- Tool runtime and power monitoring

- Dust collection control

- Air quality monitoring

Every system starts with the GRIT Hub. This device is responsible for communicating with all the GRIT devices through our Mesh network. The mesh network allows GRIT to operate wirelessly without the need for WiFi. Because the wireless communication sits on a mesh network, GRIT can scale out to very large physical installations effortlessly. Add to this the system does not require internet because it stores all the data locally. The data always stays with you onsite and secure.

GRIT is a Complete Wireless Tool Safety, Access, Maintenance and Management System for…

- Carpentry Shops

- Metal Fabrication Shops

- Advanced Manufacturing Labs

- Makerspaces and more…

Automated Dust Collection

Automated dust collection works via our GRIT Collector devices. Each dust collector that should be turned on/off will have a Collector device. We offer a range of Collector devices and can control any type. Additionally we have a GRIT VFD Collector device for Variable Frequency Drives. Shops that have large fan motors for dust collection can use a VFD to control the speed of the collector. GRIT will automatically control the motor speed depending on the tools. This can have massive electricity savings implications.

Monitor Air Quality

GRIT has an automation product for Air filters, the GRIT Air Quality device. It will turn an associated air filter on/off when the particulate matter in the air meets configured thresholds. Plus, the system can automatically turn on an air filter when a tool is turned on, pre-emptively begin filtering the air when certain tools are operated, without waiting for the dusty air to migrate to the sensor.

Blast Gate Control

Blast gate automation is performed by our GRIT Gate products. The GRIT Gate actuators retrofit onto any metal blast gate, including Nordfab style gates. Our actuators will automate metal blast gates from 2 1/2″ – 12″. The GRIT App configures which gates should be open for each tool that has a Trigger connected.

Access Safety Control

The premise of GRIT Lock is simple: easily lock/unlock tools to increase shop safety. With the use of GRIT Triggers, we are able to not only control the power that reaches your tool, but also, measure the current draw of the machine. Beyond the lock/unlock capability, the system provides an additional safety feature: Emergency Lock.

Asset Management

Manage all shop assets and consumables using a convenient kiosk style interface. Works with a scan of a barcode and swipe of the users badge. A user friendly and intuitive interface allows for quick and easy set-up of permissions. Track asset damage and repair of your most important tools.

![]()

Shop health and safety is our #1 mission statement. The GRIT Trigger is responsible for tool lockout, we call this GRIT Lock. Every tool in your shop will get a Trigger. A Tool plugs into a Trigger for power monitoring. The Trigger is in constant communication with the Hub sharing the exact state of the tool to enable blast gate, dust collection, and air filter automation.

AET Labs is an exclusive, value-added reseller, providing complete, turn-key installations for the Grit Automation system that include:

For more information, pricing and to set-up a free consultation, please contact us by completing the form below: