Office-friendly metal 3D printing in just 2 steps — Print. Sinter.

Making complex, high-performance metal parts has never been easier. Featuring a breakthrough two-step process, next-generation Separable Supports, and a software-controlled workflow, the Studio System 2 makes it simpler than ever to produce custom metal parts.

- Print to Sinter

- Software controlled workflow

- Smart Separable Supports

- User-friendly hardware

- Reliable processing

Request a Quote

Designed for Ease of Use

- No special facilities requirement

- Hands-off process

High-quality parts

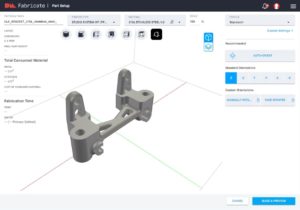

Easily produce difficult-to-machine parts featuring complex geometry like undercuts and internal channels. Fabricate, the software at the heart of the Studio System, automates complicated metallurgical processes to produce high-quality parts with densities and feature accuracy similar to casting.

Software Controlled Workflow

You don’t need to be an expert metallurgist or machinist to create complex metal parts. With our Fabricate software, native to Studio System 2, all aspects of part creation – from printing through sintering – are automated. The software automatically scales your part, orients it for print and sintering success, generates separable supports, and applies expert metallurgy to optimize fabrication.

Simply upload your design and follow the onboard UI for step-by-step guidance. Secure, web-based software constructs build plans from STL or CAD files, automatically generating supports and control parameters based on part geometry and material.

Basics:

- Software (3 hrs)

- Printer Set-up and Operations (1.5 days)

Advanced:

- Design for Additive Manufacturing (6 hrs)