How to Troubleshoot 3D Printing Issues in Older Machines & Ways to Avoid Downtime

Hey instructors! My name is Zachary Lanzo, I am the service coordinator here at AET Labs. In an effort to alleviate some stress during this particularly trying time in education history, we're focusing on bringing some practical service guidelines to our customers with our Service Notes series. We hope this info proves to be helpful and and saves educators valuable time!

The AET Labs UPrint, Dimension, & Fortus Insider Service Guide

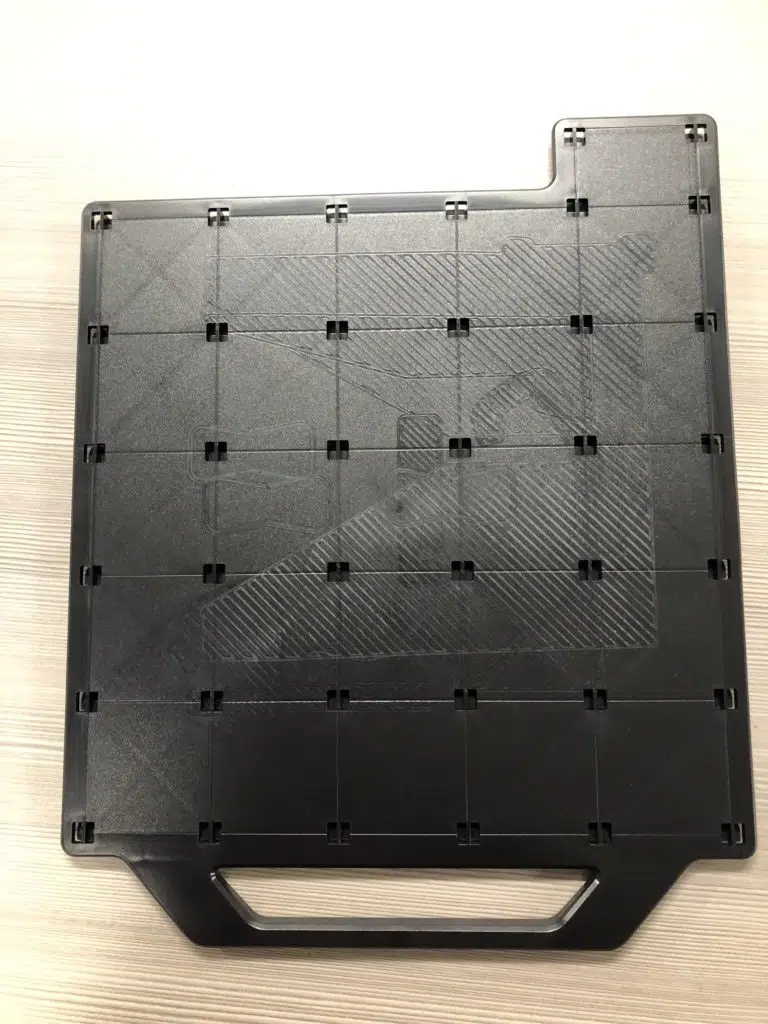

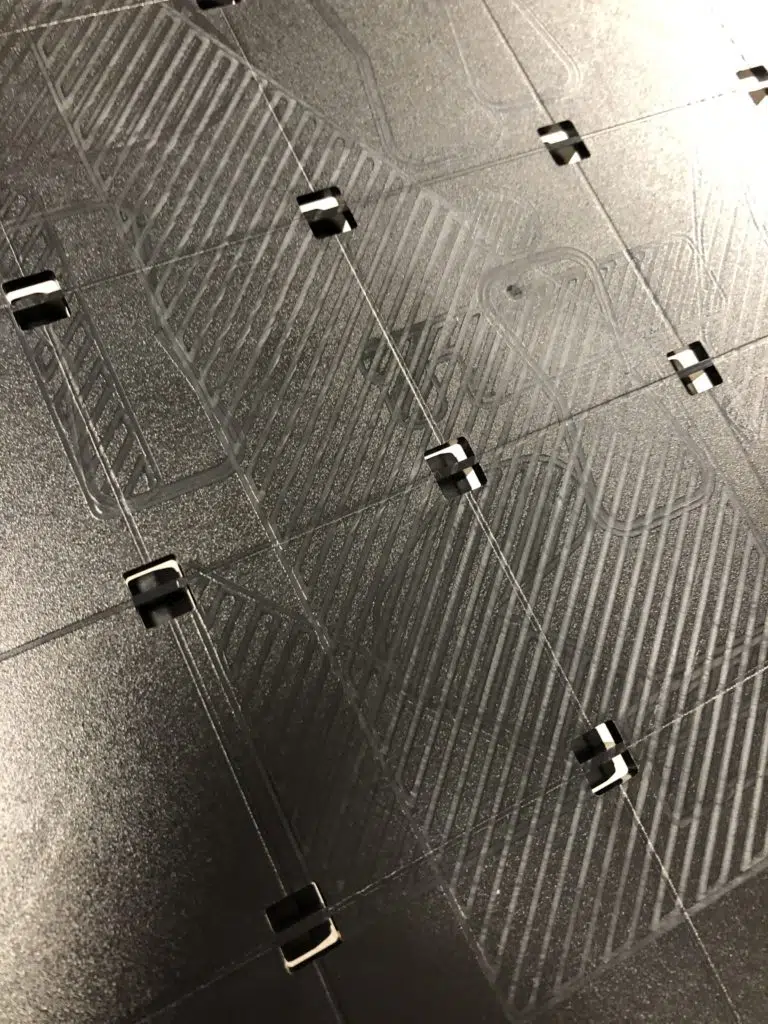

1. Use new build plates (limit stacking prints to 3x).

New trays are ideal for proper adhesion, I personally recommend limiting the "stacking" of prints to a maximum of 3 times in the same location. What is meant by stacking?

This means printing in the same position on a build plate with the same exact model. The build plate has been designed with a particular surface finish that allows for the best adhesion on the first layer. After a few prints, this surface becomes smoothed out due to the heat and looses it's ability to properly maintain good adhesion.

In one case, a customer continued having head jams. After multiple visits and and further troubleshooting, it all came down to the end user repeatedly using the same tray. This would cause the prints to lift and stick to the bottom of the head. Having a quality build plate installed for each print is critical. In the long run, the customer lost money by wasting material and the printer was down on several occasions, requiring multiple service visits.

With GrabCAD Print and even those still using Catalyst, you can re-position the model by moving it to a new position before sending the job to the printer.

Pro Tip: With the new F123 series, you have the ability to see the previous toolpath and select a new build location, by using the LCD touchscreen on the machine before starting the print.

The new F-123 series now brings you larger build trays increasing efficiency and larger prints (F370 10 x14 x 10 in.) The new thin design makes breaking and releasing new prints from the tray a breeze. A larger surface area allows maximum print build capacity.

2. Use new material.

Keeping a good check on inventory and having a good system is ideal. Properly storage and knowing when exactly any given spool was opened by marking it with a date, will hopefully prevent someone from inserting a moisture-laden spool into the machine, causing heads Issues. Stratasys marks each spool with an expiration date and any spool older than 4 years should be tossed.

Typically, 4 months after the spool is opened from the aluminum packaging, it will be susceptible to moisture. However, because or the hygroscopic nature of most filaments, from the moment the material is opened, it will be at risk of absorbing moisture. For that reason, we recommend that any open spools should be place in a large ziplock bag.

Pro Tip: AET will work with you to set-up a consumables credit, so you can use your budget when the funds are available and won't need to stock filament that could get damaged, take up extra space or even expire.

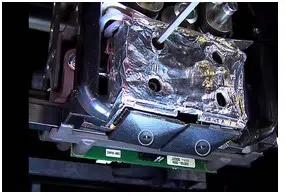

3. Replacing tips regularly (once per year).

Over time, Tips get warn out and clog up. eventually this will cause a blockage and not allow material to flow properly resulting in head jams. Tip replacement procedure is in the user guide. This is an end-user task to make sure these are getting replaced on a yearly basis.

Replace tips on old Stratasys machines can be a bit difficult for those not familiar with the procedure. Particularly the area around the tips are hot and require gloves when working on. The new F123 head design is a revolution in ease of use and more cost-effective in the long run. No longer will a service tech need to come on site to help with the replacement.

Pro Tip: Maintain a set of spare tips or additional F123 extruder for quick access in case an unplanned maintenance visit is needed.

Additionally, the new head design allows any user with little to no experience, quickly replace and recalibrate the extruders. Furthermore, with all components kept out of the heated space, no more hot surfaces to touch and new extruders can operate for over 1500 hours or more...

I am always available for questions. You can contact me at zlanzo@aetlabs.com