Pathfinder Regional Technical High School in Palmer, Massachusetts wanted to incorporate 3D printing into its curriculum while making the technology easy to access for all students. With the Stratasys F170 and GrabCAD Print, the school was quickly able to integrate easy-to-use professional 3D printing into the classroom.

WHAT THE STUDENTS ARE MAKING

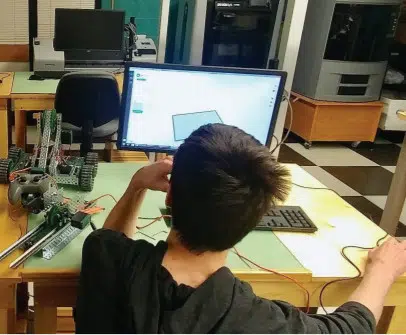

Justin Bren is a CAD instructor at Pathfinder Tech who runs the school’s print shop. He teaches students how to model parts using SOLIDWORKS and helps them find creative ways to build their creations through 3D printing. Bren likes his students to learn through working in a hands-on environment.

“And when they’re done working on assigned work, they venture off and try and create their own things,” Bren said. “I’ve got some students who are modeling creatures from their video games, some students modeling toys or robot parts, stuff like 3D printing a ring and pinion so they can put a rear axle on their robot.”

The robotics team that Bren mentors is also run out of the school’s CAD shop, so he encourages students to be creative when iterating and advancing their designs.

““I had one student who I 3D printed a ball joint for to show them how it works,” Bren said. “Then he made his own, then he made his own upper and lower A-frames, then he made his own spindle. We 3D printed it all and put it together.”

A “PHENOMENAL” CREATION MACHINE

Bren’s students use the Stratasys F170 printer in a variety of ways: to create complicated assemblies, intricate models like figurines, and even 3D printing nut and bolt blanks using a machinists’ handbook then a tap and die set on the 3D printed blanks to form threads.

“I absolutely love the Stratasys F170. That printer’s phenomenal. It’s got excellent quality and the speed is great. The models we need can be done in an hour and a half,” Bren said. “Other things that we’ll print on the F170 are very complicated models that some of the students come up with, like the characters in their video games. They don’t really come out so good on the other printers, because they don’t have the water soluble support material. That’s really opened up a lot of possibilities for the students to create a lot of these intricate designs that we otherwise wouldn’t have a way of getting the support material out.”

BENEFITS OF USING GRABCAD PRINT

While Bren’s students might be using their Stratasys F170 to print some pretty complex models and designs, when it comes to using GrabCAD Print most of them seem to have no problem learning the easy-to-use software. “GrabCAD Print is very intuitive. I’d say it takes me less than 3 minutes to show them how to use it and they’re off and running,”

Bren said. “I really like showing the students how to set up their trays and orient their models. With the orientation tool you can go in and punch in that you want to rotate the model 1-degree on the Z-axis and start incrementing, so you can really work on fitting everything on one tray and maximizing the use of the tray.”

CONCLUSION

GrabCAD Print makes printing parts on the Stratasys F170 3D printer easy, educational and fun for the students of Pathfinder Tech and its robotics team.

Courtesy of GrabCAD 9 Camp St 2nd Floor Cambridge, MA 02140 USA (617) 825-0313 www.grabcad.com