Key Takeaways

- Educators should explore the full range of Stratasys materials, including high‑performance thermoplastics, elastomers, and multi‑color photopolymers, to expand students’ design and prototyping capabilities.

- Incorporating scaffolded 3D printing projects, from concept to functional parts, helps students develop skills in design, iteration, and real‑world application.

- Offering a Stratasys FDM certification and maintaining routine service support ensures your 3D printing program remains industry-relevant and reliable.

Stratasys 3D printers are built to perform in busy classrooms and labs, giving students access to the same professional-grade technologies used in the industry. But are you tapping into the full potential of your Stratasys 3D printer? At AET Labs, we work with educators across New England to help them maximize the impact of their engineering, CAD, and advanced manufacturing programs using 3D printers. Here are some tips, resources, and ideas to get even more value from your Stratasys printer.

1. Revisit Your Materials

Stratasys 3D printers give students access to a wide range of materials that support real-world, hands-on learning. PolyJet printers allow for ultra-realistic prints using materials like multi-color Vero photopolymers, flexible, rubber-like elastomers, and much more. Stratasys FDM printers support high-strength, industrial-grade thermoplastics, including carbon fiber-reinforced materials and biocompatible options for medical and food packaging applications.

If you've been sticking with one or two materials, consider expanding. Exploring different materials can help students learn about mechanical properties, prototyping for different use cases, and how to match materials to real-world manufacturing needs.

2. Integrate New Projects

As students are introduced to 3D printing technology at earlier stages, they become better prepared to take on more advanced challenges throughout high school and into college. Stratasys 3D printers support this progression with a variety of real-world applications that include design and concept modeling, rapid prototyping, and part production.

Need 3D printing project ideas?

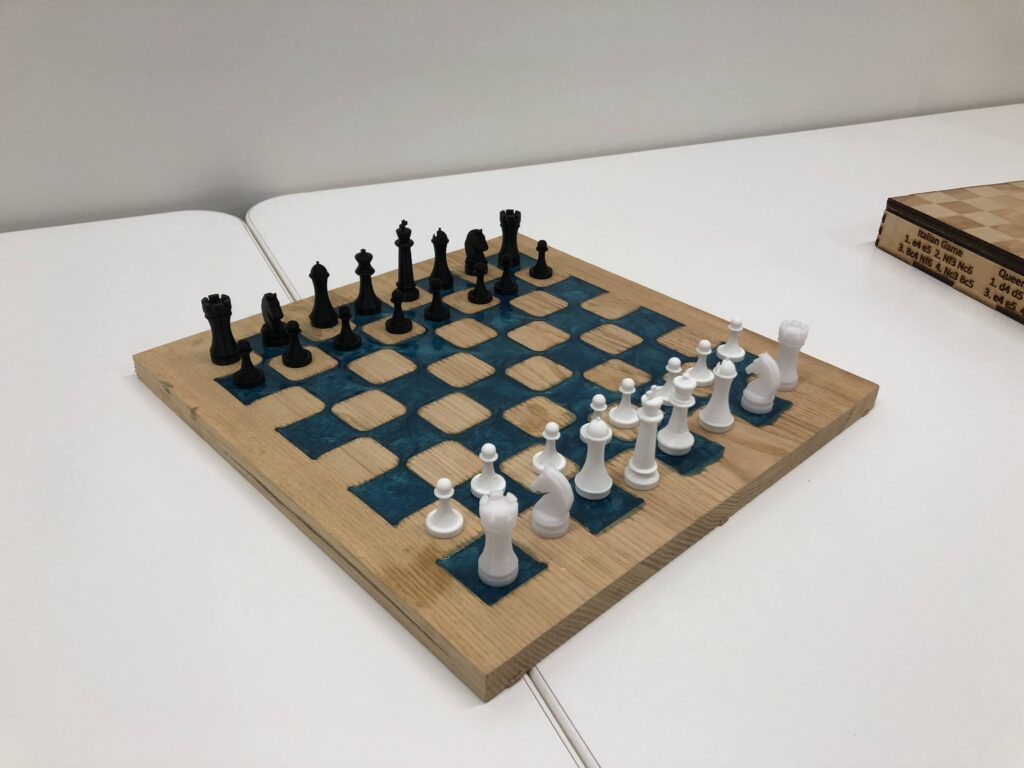

Melrose High School created 3D printed game pieces for chess and battleship.

MIT's Toy Product Design Class uses the Stratasys J55 to develop colorful working toys.

In the rapid prototyping lab at Wentworth Institute of Technology, students create 3D printed assemblies of moving parts with Stratasys machines as their final project.

Reach out to AET Labs to talk about your curriculum goals, and we can help you with even more inspiration.

3. Give Students an Industry-Recognized Certification

Another way to equip students with real-world skills is by certifying them with a Stratasys FDM certification, backed by NOCTI. This credential covers additive manufacturing technologies, industries and applications, FDM and PolyJet materials, key technology specifications, design considerations from CAD to CAM, fabrication considerations and post-processing methods.

In New England, certified institutions include Diman Regional Vocational Technical High School (Massachusetts), Berlin Public Schools (New Hampshire), York Community College (Maine), Harvard University (Massachusetts), and more.

4. Plan for Maintenance with Local Support

3D printers can get heavy use in the classroom. Routine maintenance ensures that things run smoothly and minimizes downtime during peak periods. AET Labs offers service plans and preventive maintenance packages for Stratasys systems. If you ever run into issues, Partrick Corcoran, AET Labs' Support Team Coordinator, is here to help.

Patrick has been in the technical service industry for the last 15 years, working on a variety of machines over his career, including fax machines, digital black and white and color copiers, print presses, wide-format inkjet printers, 3D printers, laser cutters, and CNC machines. At home, he enjoys 3D printing as a hobby with his kids. He has a Bambu X1C FDM, Bambu H2S, and Anycubic Photon 4 Resin 3D printer. Patrick works with AET Labs customers, handling electro-mechanical troubleshooting and break-fix for both the Stratasys F123 and PolyJet J series. He also assists with software and firmware updates.

Take Your Program Even Further with Stratasys 3D Printers

You've already invested in a high-quality 3D printing solution. Make sure your institution and students are getting the most from it by exploring new materials, applications, and certifications.

AET Labs is here to help you stay ahead. Contact us with any questions or support requests related to your Stratasys 3D printer.