When it comes to choosing the right equipment for your program or lab, who better to guide the process than those who have also taught in a classroom? In this post, we’re bringing you insights from two members of our AET Labs’ sales team—both former teachers—who now help technical schools, colleges, and universities make smart decisions about equipment to help students learn industry-relevant skills. Their first-hand experience in education shapes their approach, ensuring that each recommendation is as practical as it is impactful.

Meet our Teachers-Turned-Technology Consultants

Mark Lyons, AET Labs’ VP of Sales, is a former CAD teacher with 15 years of experience at Assabet Valley Regional Technical High School and Bay Path Regional Vocational Technical High School. Since leaving the classroom, he has remained a committed member of the CAD teaching community. He has been leading an annual professional development summit bringing together CAD teachers across New England since 2007. As an active supporter of the Massachusetts SkillsUSA competitions for 20 years, he has run competitions across many categories, from laser engraving to additive manufacturing. He also serves on advisory boards for multiple CTE schools in New England.

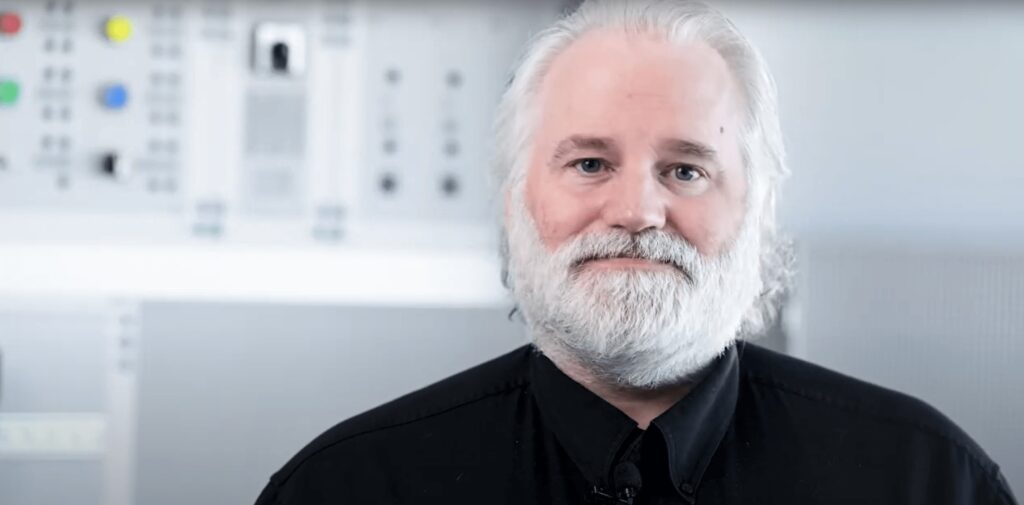

Phil Ranger, one of the Technology Consultants at AET Labs, taught electrical engineering technology for 11 years at the college level in Canada (similar to CTE in the United States) and spent two years as a university lecturer in electrical engineering and computer engineering. After Phil’s teaching career, he joined Festo Didactic and trained instructors internationally on how to use new technologies and theories in the classroom. As part of the AET Labs team, Phil is a member of advisory boards for CTE schools in New Hampshire.

5 Tips for Choosing Equipment for Technical Education Programs

With their unique perspectives as former educators, Mark and Phil offer these five tips to guide schools in selecting equipment that engages students and aligns with learning goals.

1. Start with the Big Picture

Mark: Teachers tend to worry about the budget. They don’t think their school has money for their program or to buy equipment. I try to coach them on coming up with a vision for their program and letting their administration find the money. Teachers might not realize grants are out there that can be used to buy the equipment they need.

Phil: In my past work at Festo, I helped educators build programs from scratch, so I incorporate that into my approach to working with instructors now. I try to understand the nuts and bolts of what teachers and professors need to teach and take a holistic approach to link their goals to how to best teach theory and hands-on experiences. My approach is to help identify the teaching goals and match that with the right equipment. It’s not just about having the flashiest machine in a lab.

Mark: As a company, we try to recommend equipment students would see in the industry. It helps students when they move along to get this experience, even if it’s more expensive. This type of equipment benefits the students and the school because it’s industry-relevant and high-quality and reliable.

2. Don’t Reinvent the Wheel

Mark: I like to bring equipment to instructors that have a curriculum with them. They can use that to get started, customize the curriculum as they see fit, and build on it over time.

3. Help Students Learn with Engaging Technology

Mark: One phrase I often say is “engaged and motivated students learn.” If students have fun with the equipment and technology, they will learn. Students get excited learning about 3D printing and students love using AR/VR technology like zSpace. Once you have them hooked, they will want to dig deeper and learn.

Phil: Students who graduate from college having only learned engineering theories are not the best hires for companies. Students who get realistic hands-on experiences with equipment have a deeper understanding of how to apply the theories in a work environment. We provide equipment that comes with curriculum materials that are easy for students and instructors to understand and bridge theory with realistic experience.

4. Align Equipment with the Curriculum

Mark: I look at state frameworks to help teachers pair equipment with the frameworks and their curriculum. It helps them put the puzzle together and select the right equipment they should have for the class.

Phil: I ask instructors what they want to teach and match equipment that fits instead of forcing equipment into the program.

5. Work with a Partner

Mark: Our team at AET Labs is more than a sales team; we’re a resource. We help instructors get a wider view of what’s going on in the industry and introduce new technology. They don’t need to look around for what’s current—we bring that to them so they can move their programs forward.

Choosing the right equipment can be a big decision for a school or university, and we’re here to help make it easier. With firsthand experience and a deep understanding of classroom needs, our team of technology consultants is ready to guide you in selecting equipment and technology that will inspire and engage your students.

Contact AET Labs today to schedule a free consultation for programs at your New England technical school, college, or university!