Labs are vital hubs within colleges giving students ways to explore, learn valuable skills, and build confidence. Most labs have a diverse mix of equipment and tools, and as the lab director, you're tasked with keeping it all under control, which could be a lot to manage when hundreds of students come through a lab each day. Fortunately, there is a way for directors to get help managing labs and shops: GRIT Automation.

What is GRIT Automation?

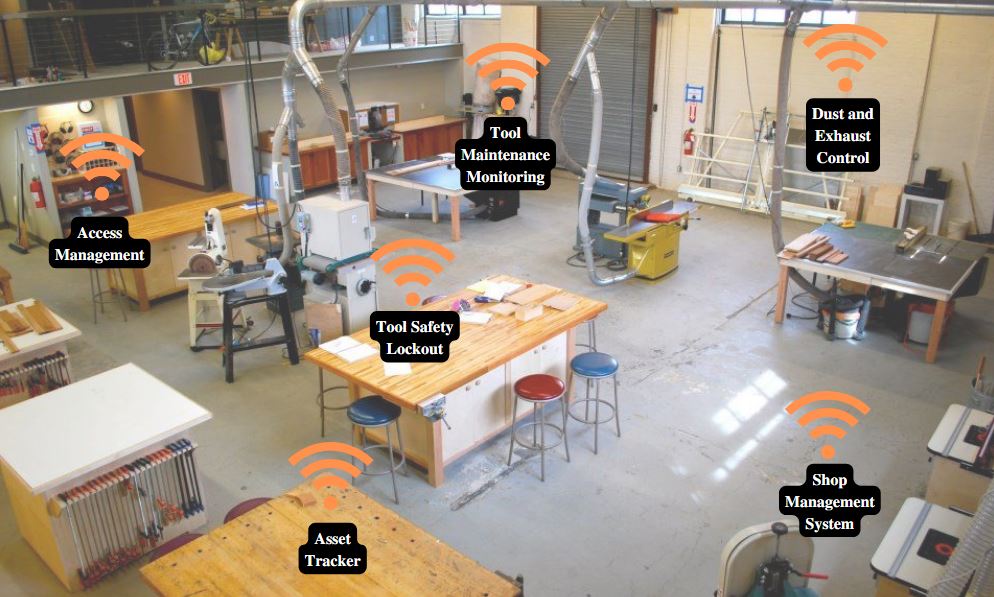

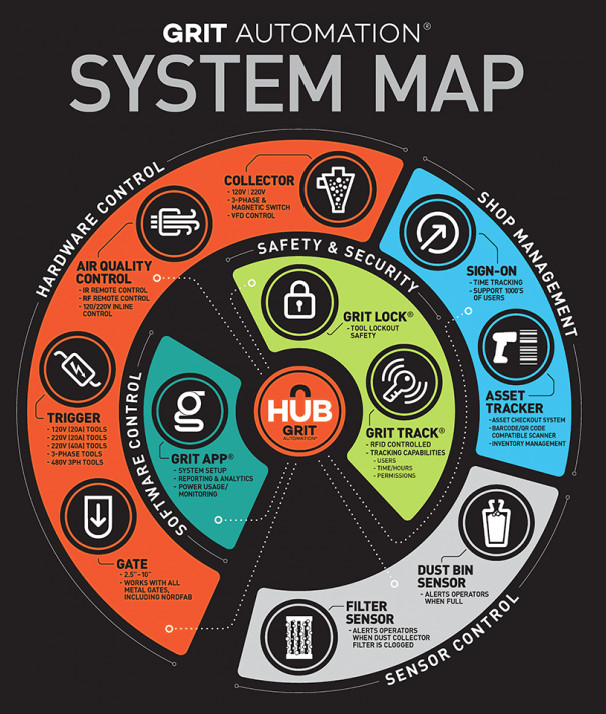

GRIT Automation is a wireless automation platform to help labs and workshops, focused on health and safety. The GRIT platform automates the safety, security, and air quality of most lab types including carpentry shops, metal fabrication shops, advanced manufacturing labs, and makerspaces.

Benefits of the GRIT Automation Platform for Labs

GRIT Automation seamlessly integrates with new and existing labs. It runs on a propriety mesh network, so it doesn't need your internet to run and can scale to large physical spaces. After set-up, students use the lab as they normally would, and the system automatically adjusts based on what tools they are using. As the lab director, you get access to usage data from the GRIT app on a phone, computer, or tablet. Here's what GRIT Automation can do for your lab:

Keep students safe

The GRIT Lock helps students with lab safety by operating equipment through an RFID badge. To start a machine, students swipe their badge to lock and unlock it. You can set access for students based on their level of experience and training. In addition, you can control the power that reaches the tool and measure the draw of the machines when in use.

Manage your lab inventory

You can keep track of all of your shop assets and consumables with an easy check-out process. During set-up, a barcode is added to each item, and when a student wants to use a tool, you scan the barcode and swipe their badge. You can easily set up permissions for individual students and track asset damage and repair for your tools.

Automatically collect dust and keep your shop clean

The GRIT Collector devices collect dust from machines automatically. You can also turn dust collectors on and off and control collectors from the app. For shops with large fan motors for dust collection, you can use a GRIT Variable Frequency Drive (VFD) to control the speed of the collector. GRIT will automatically control the motor speed depending on the tools, saving you electricity costs and keeping your shop clean. You can also add GRIT gate control devices to your existing metal blast gates.

Monitor lab air quality

GRIT will automatically turn air filters on and off when the particulate matter in the air meets configured thresholds. The system will also turn on the air filter when a tool is turned on, or pre-emptively begin filtering the air when certain tools are operated without waiting for the dusty air to migrate to the sensor.

How College Labs Use GRIT Automation

GRIT gives the facility operations specialist at the Siebel Center of Design at the University of Illinois peace of mind. It allows him to train people on certain tools and give permissions when students know how to use equipment properly. If a student uses a machine in a way they're not supposed to, they can remove permissions and train the student again. They also use the asset tracker to manage lab inventory so tools don't go missing from the shop.

At the Krannert Center at the University of Illinois students are trained on tools using OSHA guidelines. After training, the associate technical director uploads the results into the GRIT system and students get access to the tools they are trained on. If a tool is consistently breaking they can access data to see who was using it and retrain them or adjust their training.

Are you ready to get help automating the management of your lab? AET Labs is an exclusive partner to GRIT Automation, helping colleges and universities across the country design and install the platform in their labs, with options for training and service in New England. Contact us today to get started!