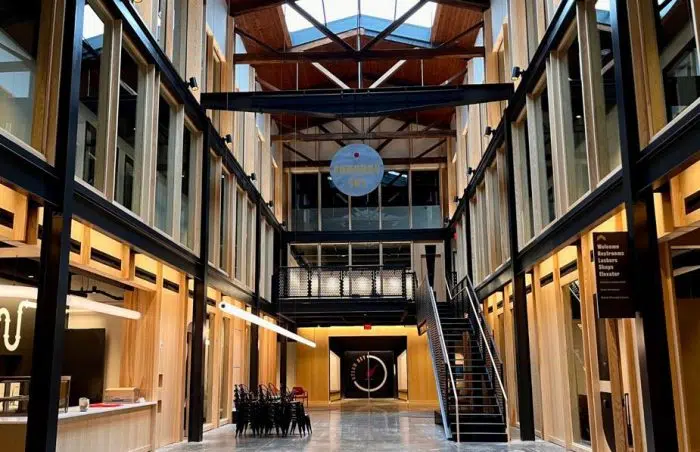

When we reflect on the work we completed this summer, two things stand out: our teamwork and our impact on Massachusetts communities. The AET Labs team achieved a new milestone by completing equipment installations at three new construction projects that happened simultaneously. Each educational institution will provide new creative and technical outlets to its communities, from citizens of Cambridge at The Foundry to "tough tech" entrepreneurs at The Engine in Cambridge to ambitious high schoolers at Attleboro High School. Countless hours over weekends and summer breaks were put into these projects by the AET Labs team, and we're proud of the meaningful work we contributed to Massachusetts communities. Here's an inside look at what our team accomplished for these projects.

Establishing Goals

Each project began with setting goals and a vision for how the buildings will benefit their communities. These conversations happened over a year ago, so we knew it was essential to help each group select equipment that would serve their communities for years to come by introducing them to cutting-edge technologies used in the industry. For Attleboro High School, we led vision planning meetings bringing together administration and teachers to establish their goals, including adding new CTE programs and shops to their Chapter 74 programming. For The Foundry and The Engine, we reviewed initial equipment lists, providing recommendations to meet the needs of their spaces.

Designing the Labs

We have heard from many schools frustrated and embarrassed that they ordered equipment too big to get through their doors. Or they ordered equipment without realizing that they needed a water source or ventilation to the outside. Purchasing technical equipment for a new construction school, university, or community center involves a solid understanding of the space constraints, equipment specs, and design aesthetic. For Attleboro High School, we worked closely with KBA architects providing feedback on layouts to ensure they incorporated mechanical, electrical, and plumbing specs into the designs. As construction got underway at each location, we visited construction sites. At Attleboro High School, we coordinated with Consigli Construction to make sure oversized pieces of equipment were delivered before they closed in walls and doors.

Selecting the Equipment

Choosing the right equipment for technical labs and makerspaces early in the construction process is critical. New labs need many items—equipment, storage, tables, tools, and more. For a new construction project, the institution could require hundreds of items that are ordered from multiple manufacturers across the globe! And a new reality this summer was needing to place orders early due to supply chain issues. For The Foundry, The Engine, and Attleboro High School, we handled all the equipment coordination for the labs we worked on. We helped the institutions select the right equipment, reached out to manufacturers and suppliers, prepared detailed product specifications, and placed orders. Each institution had one person at AET Labs to contact for all equipment needs.

Centralizing Deliveries

Construction sites are very busy, and taking in deliveries for equipment not ready to be installed is distracting for a construction project. So our AET Labs team took this disruption away from the construction teams by centralizing equipment deliveries across the labs to a separate warehouse while construction was underway. When the buildings were ready, all equipment was delivered to the locations together. In some cases, not all equipment in these labs were new. The Engine and Attleboro High School had previous locations with existing equipment to move to their new buildings, which we also coordinated.

Installing and Commissioning Equipment

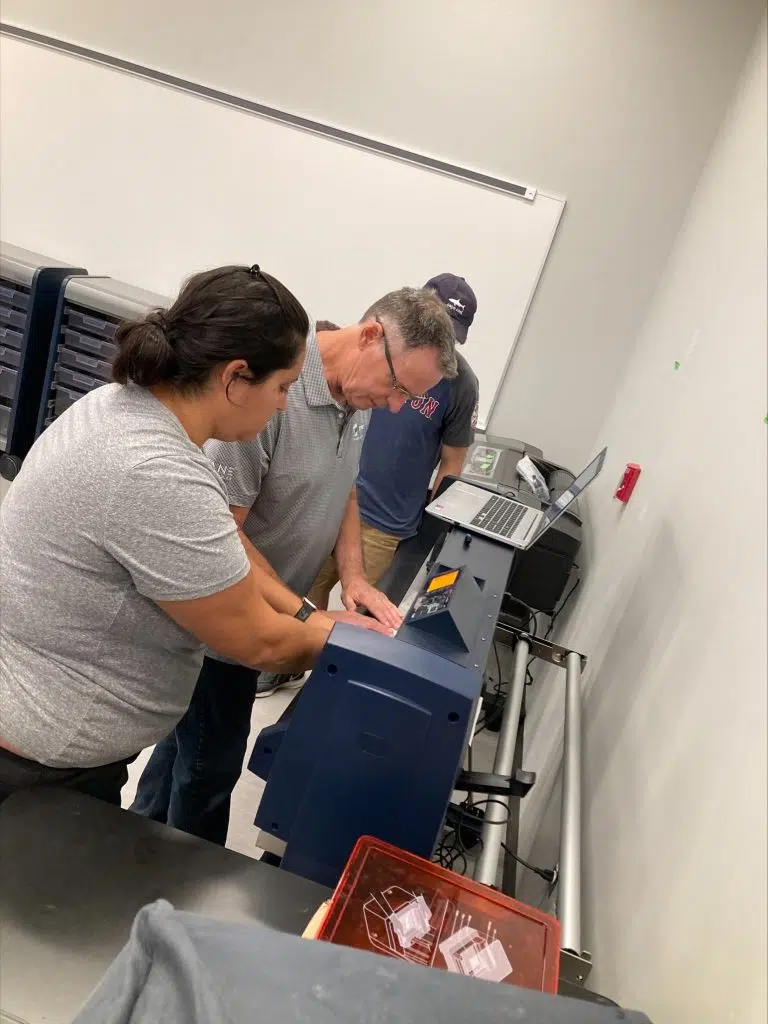

Training systems that came with hundreds of parts. CNC machines that weighed thousands of pounds. Dozens of machines that required computers, software, and networking. Our team collaborated to install and commission all equipment across the three construction projects. It was all hands on deck for our team as we worked together to unbox, assemble, test, and set up hundreds of items across The Foundry, The Engine, and Attleboro High School.

Training Instructors

We get disappointed when we see shiny new equipment in new labs not being used because instructors don't know how to operate them. So for each project, we went on-site before doors opened to train instructors and lab managers on the operation and maintenance of their new equipment. We will be returning throughout the year to provide further training on the equipment, including how to incorporate them into their curriculums.

We know these new labs will serve their Massachusetts communities well. We're honored that AET Labs was part of the broader team that contributed to completing these three meaningful projects that will prepare students for careers, inspire community members, and contribute to growing entrepreneurial ventures.

Now that these are complete, the AET Labs team is in the planning stages for the next round of new construction projects and ready for more! If you are planning to build any new technical or STEM labs, buildings, or schools in New England, we're here for you. Contact us to get started.