The AET Labs team had a busy year helping New England schools with their labs! From being a part of new labs to training instructors to assembling machines and servicing equipment, we're happy to have worked with many innovative instructors this past school year.

Here are some project highlights from our team members:

Northeastern University in Massachusetts

"Industrial Automation has always been an area in which I've had a special interest. I enjoy watching individual components, such as air cylinders, motors, conveyors, robots, and sensors, come alive and work together to form an entire system to ultimately create something. With the adoption of Industry 4.0 technologies, these systems have taken on another level of complexity, allowing technicians, managers, suppliers, and customers to receive real-time system and/or product information. I also get a lot of satisfaction when schools in our region commit to go all in and create a new program that revolves around this technology.

That's exactly what Northeastern University did when they built a brand new space called the Mechanical and Industrial Engineering Manufacturing (Cyber-Physical) Systems Teaching Laboratory to accommodate the Festo CP Factory for their undergraduate and graduate students. The system will be used to demonstrate the latest mechatronics technologies and teach the highest levels of automation processes. With two separate islands of automation, the CP Factory features a mobile robot working between systems to replenish raw materials and deliver finished goods. In addition to the ten stations of assembly processes, it also includes an CNC Lathe, Laser Engraver, 7-axis Robot on a linear rail, Collaborative Robot, and so much more. This new lab will help make Northeastern leaders in the research and application of this important technology." - David Kempskie, Principal and Founder

Sanford Regional Technical Center in Maine

"Sanford Regional Technical Center has been outfitted with 3D scanning, 3D printing, and laser cutter technology from AET Labs. Situated in a modern and well-tended CAD drafting lab, I visited with instructor Russell Clark to orient him to his new Epilog Fusion Edge laser. No stranger to integrating a laser cutter into high school curriculum, I was impressed by the various projects, both laser engraved/cut and 3D printed, displayed in the room's showcase. I was particularly struck by a series of house framing projects in which all the components were laser-cut plywood. Producing scale models is a common CAD drafting project. However, students typically use manual hand or machine tools to produce the stock (think mini 2x4's). With a laser cutter, the process of producing stock more closely resembles a real manufacturing environment, and is done on a system that high school students are able to control from start to finish." - Adam Zelny, Applications Specialist

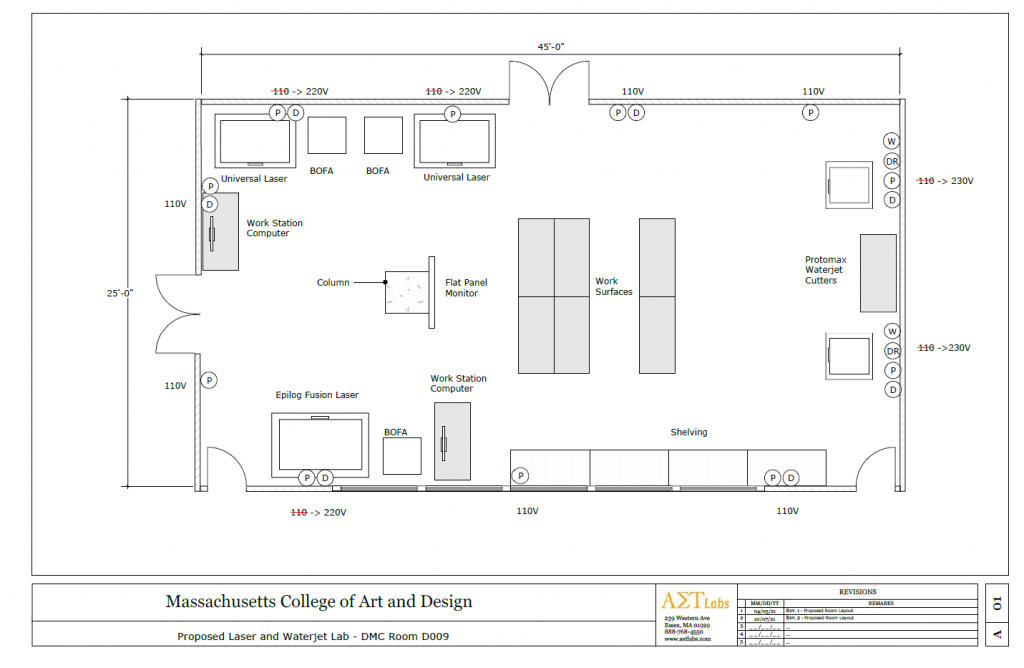

Mass College of Art and Design

"Mass College of Art and Design desperately needed a technology upgrade. What should be one of the hubs for design and creativity in Massachusetts was using technology that was decades old, which was hindering their ability to create in the 21st century. Using funding through the Skills Capital Grant, they are in the midst of a major overhaul of the available equipment to their students. They have added a CNC mill and lathe for machining metals, 2 CNC routers for woodworking projects, several industrial grade 3D printers, laser cutters, 3D scanners, CNC wire benders, and more. The centerpiece of this whole project is a beautiful makerspace that overlooks the Evans Way Park. I'm excited to see the creativity that comes out of MassArt with all of the new technology available to them. - Matt Campbell, Technology Consultant

Central Connecticut State University

"I've had the pleasure to help outfit several engineering labs at Central Connecticut State University in their brand-new state-of-the-art Applied Innovation Hub building, which houses the School of Engineering, Science and Technology department. They have added Festo Electromechanical Training Systems, Festo Mechanical Drives Systems, 3D Printers, TecQuipment Heat Transfer Systems, Quanser QBots and Qube Servos. These labs are poised to offer CCSU students the most advanced technology and become an attractive destination for prospective students. The project has been very exciting for AET Labs and me to be a part of, and we are looking forward to continued success at CCSU in the future as these programs will help grow the engineering field in the State of Connecticut." - Justin Turski, Technology Consultant

Medford Vocational Technical High School

"The Medford Vocational Technical High School Robotics Team built an underwater ROV that won the Mate ROV New England Regionals, and they represented New England at the World Championships! Students used an Epilog Laser and FormLabs 3D printer to create some of the parts." - Chris Macrina, Technology Consultant