3D printers are among the most prevalent pieces of equipment in technical labs, from middle schools to university research labs. With hundreds of 3D printers on the market, it can be overwhelming to decide which is best for your classroom. We interviewed Adam Zelny, Applications Specialist at AET Labs, who trains instructors across New England on how to best use lab equipment for curriculum needs. He shared some factors to consider, beyond price, when purchasing 3D printers for classrooms.

There are hundreds of 3D printers on the market. How do you suggest instructors determine which is best for them?

I’ve found that the least expensive 3D printers often include steeper learning curves to get optimal results. These machines are also more prone to develop issues, sometimes due to user error because of misuse. By no means do I think this is a bad thing. It is a perfect solution if you run a lab or classroom that encourages understanding mechanical engineering. You have the time and resources to conduct a lot of troubleshooting and make repairs on your own or teach students how to do them.

On the other hand, high-end printers will provide reliable results over time, leaving you the option to dig into how a 3D printer works or reap the rewards of unique prints for your 3D modeling and engineering projects!

Besides the price, what are some differences between low-cost and higher-priced 3D printers?

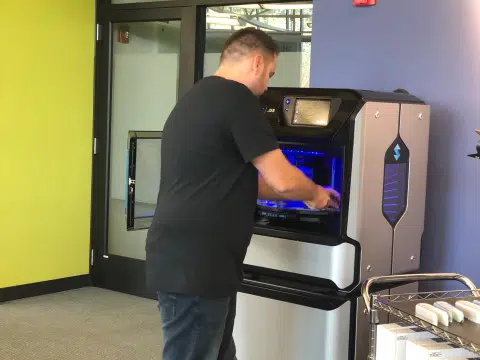

Aside from what has already been mentioned, the most significant differences are precision and capability. The high-end printers will provide a smaller range of deviation from a digital design to the physically printed model. If you plan to challenge your students with assembly-based designs that include moving parts or fittings that interface with objects made from a different type of machine, something like a Stratasys F123 series machine is a great choice. With these machines, you also have the option to expand which materials your parts are produced with, ranging from inexpensive PLA to a flexible rubber-like material in TPU. While this option can be present in some low-cost machines, knowledge of material dynamics can be helpful when setting up the parameters of a print.

What are some creative ways you’ve seen instructors use 3D printing technology in their classrooms?

I have seen teachers incorporate 3D printed models into various classroom projects, including structural parts for robots, custom jigs for hand tool-based machining, and connection fittings for woodworking projects. I met one high school teacher who proudly displayed over one hundred student projects in a showcase in his classroom. It was evident that every project required components that fit together to produce a working mechanical assembly.

How do 3D printers prepare students for the workforce?

Some of the high-cost printers we’ve been discussing are being used in educational and industrial facilities. Companies like Airbus and Volkswagen use 3D printing to produce custom components that aid in manufacturing departments. They even 3D print end-use parts that you might find in an actual vehicle and not even realize it’s 3D printed! High definition and multi-color printers from Stratasys are being used for prototyping aesthetically oriented consumer products like earbuds and smartwatches. When students begin learning about 3D printing they have already taken a step toward understanding how modern companies are innovating with product development.

How should instructors get started incorporating 3D printers into their curriculum?

If you are new to having access to a 3D printer in your lab or classroom, an immediate challenge is to ask your students to design something that would augment the classroom or its tools in a potentially productive way. Starting with small projects is vital for those new to the technology. If your curriculum already entails drafting CAD models and producing physical parts using machine tools, then you will have a head start! You could move right on to making mechanical assemblies or tooling to aid with other manufacturing projects.

Need help finding 3D printers for classrooms? AET Labs can help you decide what is best for your curriculum needs and help you identify grant opportunities.