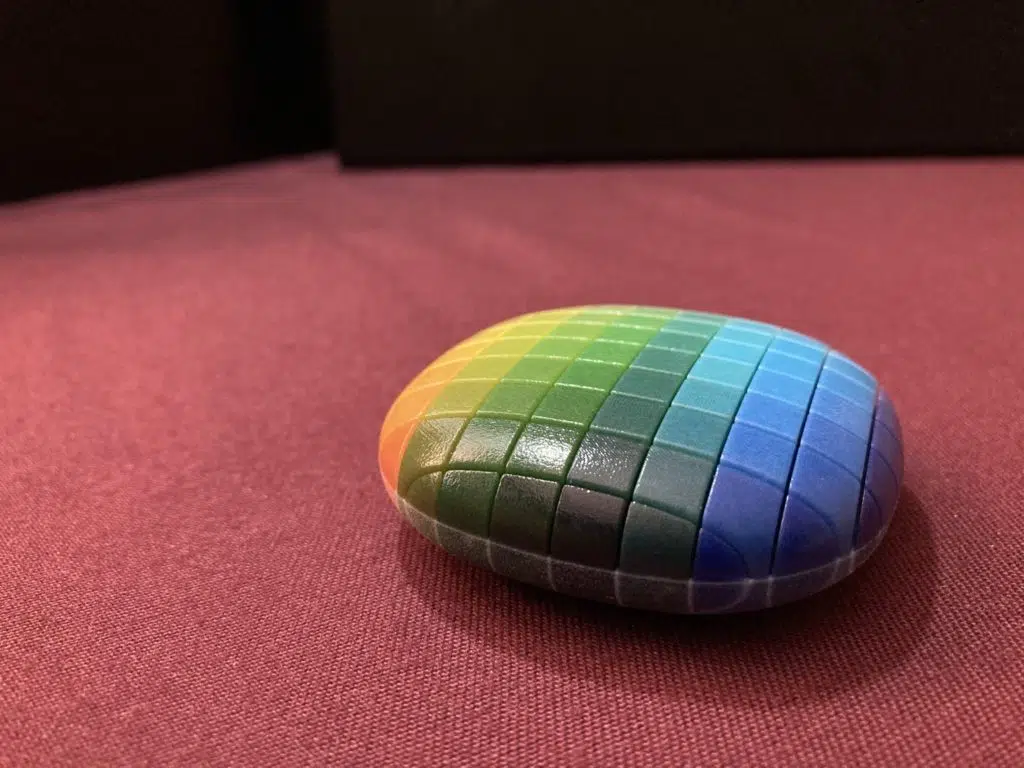

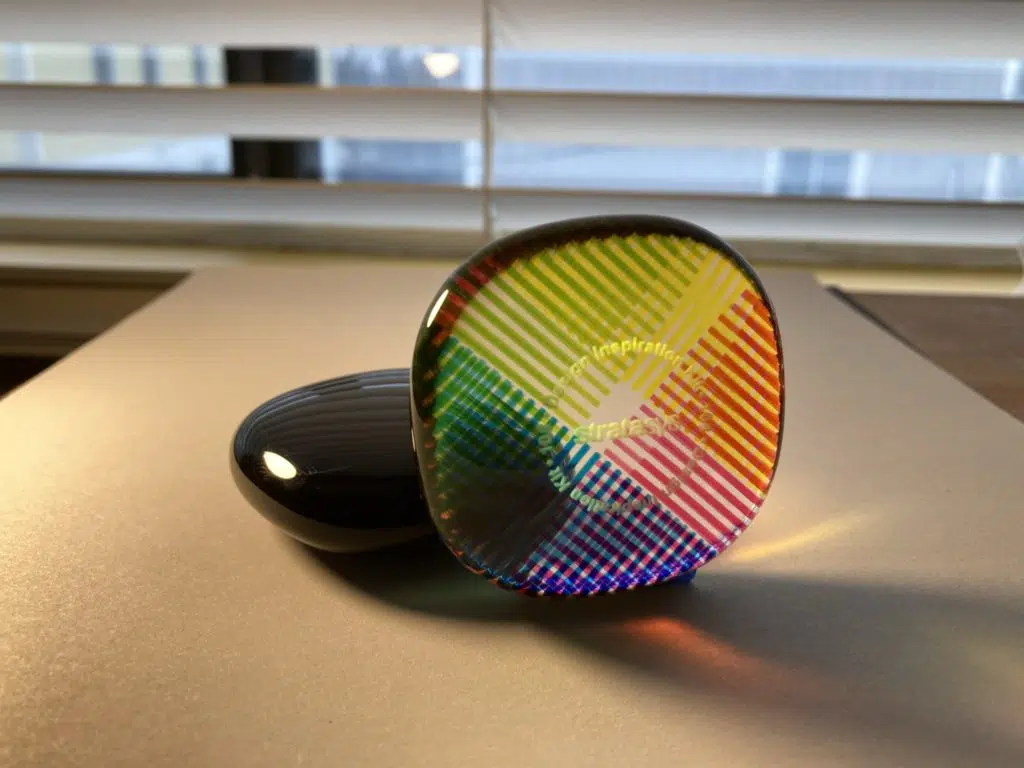

The following images are "design pebbles" from a Design Inspiration sample kit, allowing you to imagine what you could do with PolyJet 3D printing. Each pebble represents a unique capability — made possible with the Stratasys PolyJet J55 and/or J8 Series systems.

- Each pebble takes about three hours each to print and uses approximately 0.1 kg of material (approx. 80-100 g model material, 30 g support material).

- Post-processing for samples may include hand sanding and buffing, sand blasting or photo bleached.

- Polyjet resins include Agilus30, VeroBlackPlus RGD875, VeroClear RGD810, VeroUltraClear, VeroPureWhite RGD837, VeroVivid - YellowV, MagentaV, CyanV