First published on the Stratasys blog on October 9th 2019, by Jessica Coughlin.

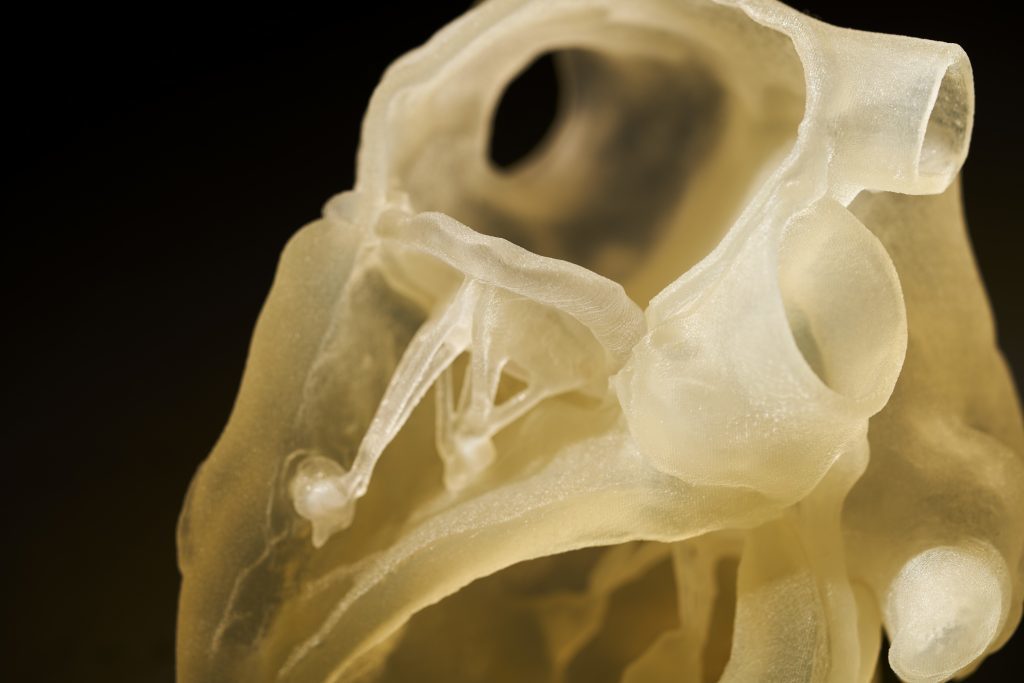

As Stratasys-watchers know, we’ve been able to produce incredibly realistic-looking parts of the human anatomy on the J750 for a while now, leading to some remarkable stories, like the kidney cancer story we profiled at Bordeaux University Hospital.

However, with Digital Anatomy, we’re now boldly venturing into replication of the actual feel, responsiveness, and biomechanics of human anatomy. That’s important because up until now, the only real way to represent human anatomy well is on a human being. And that’s not always a good idea.

The other options all have significant shortcomings. To cite just a few:

- Cadavers are highly processed and, by definition, lack “live tissue feel.”

- Animals only approximate human anatomy and present ethical concerns.

- Traditional 3D models lack the biomechanics for optimal product training and testing.

- Virtual reality lack haptic feel and the ability to simultaneously view from all models.

- It’s unlikely that animal, cadaver or existing synthetic models will include the pathology of interest.

The Digital Anatomy 3D Printer addresses all of these issues. For example, when used with the new TissuesMatrix™ material, we can effectively simulate functions like tear resistance, cutting resistance, suture pull force and valve regurgitation. With GelMatrix™ for cardiovascular anatomy, we can simulate burst pressure, guidewire insertion force, and aneurysm burst pressure. BoneMatrix™ can simulate tapping, reaming, spinal alignment and sawing. All of these and others are being clinically tested today.

The new Stratasys J750 Digital Anatomy 3D Printer has the power to create true “digital twins” – with the look, feel, and function of real organs

The new solution includes new software in which you choose anatomies, not materials. The proprietary voxel-based slicer automatically generates the microstructures required, right down to different bone densities. The user can then modify the characteristics to replicate the desired patient demographic as needed.

The new Stratasys J750 Digital Anatomy 3D Printer has the power to create true “digital twins” – with the look, feel, and function of real organs

These “digital twins” have wide-ranging uses. Academic medical centers are expected to embrace them for efficient and cost-effective training on a range of pathologies, enabling clinicians to learn and develop skills prior to entering an operating room. Medical deviceMakers can use the Digital Anatomy models to optimize design throughout the product lifecycle by performing design verification, validation usability studies, competitive comparisons and failure analysis.

The latest healthcare solution from Stratasys has been years in the making, and new applications are expected in the future.

Learn more about the Stratasys J750 Digital Anatomy 3D Printer.