By Michael Gaisford, DIRECTOR OF MARKETING, MEDICAL SOLUTIONS, Stratasys

Amid intensifying health care challenges like rising costs, an aging population and payer focus on outcomes, 3D printing can play an integral role for medical device companies seeking an edge in innovation, physician education and training, manufacturing and sales.

Join this 60-minute webinar to learn more, as Dr. Scott Rader, PhD, General Manager, Medical Solutions, Stratasys, and Dr. Vicknes Waran, Centre for Biomedical and Technology Integration (CBMTI) in Malaysia, discuss how 3D printing reduces costs, improves care and increases speed for a wide range of medical procedures and devices – with potentially life-changing impact.

Topics covered include:

• Innovation and product development

• Preclinical testing

• Manufacturing

• Clinical education and marketing

• Surgical planning and execution

• Lifecycle management

See how CBMTI uses 3D printing for:

• Developing effective models for surgical training

• Patient-specific molds and guides

• Surgical planning

• Rapid prototyping

• Other applications within the healthcare environment

Who should attend:

Medical Device Manufacturers, R&D, Product Development, Marketing, Product Management, Professional Education, and Clinical and Preclinical Testing.

More about CBMTI

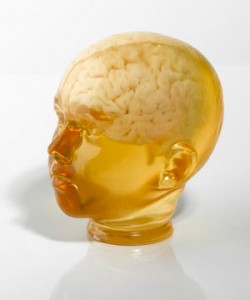

Founded in 2007 with the goal of providing the physicians at the University of Malaya with a source for custom cranial implants, the Centre for Biomedical and Technology Integration (CBMTI) has grown and evolved its mission through the power of 3D printing.

Acting as a center of excellence within the university, CBMTI’s journey into the world of 3D printing is typical: Start with a specific use case with clear benefits and tinker with the technology to test its limitations and capabilities across the organization’s entire mission. CBMTI expanded its use of 3D printing beyond custom cranial implants and into clinical training for complex neurosurgery procedures, pre-surgical planning with patient specific models, developing surgical molds and guides, rapid prototyping of new medical devices and creating efficiency tools to streamline both research and patient care.

Next Gen Training for Tomorrow’s Neurosurgeons

Where CBMTI truly excels is in creating clinically relevant and realistic clinical training and education models. Training neurosurgeons is a significant investment and involves an apprenticeship model in which experts mentor trainees as they conduct high-risk, clinically challenging procedures. Trainees observe many procedures before they are given the chance to test their own skills. They often develop skills piecemeal, performing small portions of many procedures under expert guidance.

In contrast, physicians trained using CBMTI’s 3D printed training models are able to train on a given procedure from start to finish. Trainees work on a model created with specific pathological problems, using the actual tools the procedure requires. With this approach, the model can be designed to simulate unexpected complications and anatomical variation without putting patients at risk. The technology has the potential to revolutionize the way surgeons are trained and educated.

Join today to see how 3D printing can shape clinical outcomes and corporate profits. Register here.

And to keep up to date about the latest advances in 3D printing for medical applications, please click here to sign up for the Stratasys Medical Innovation Series.