Who is Techno CNC? Techno is a manufacturer of high quality CNC Router systems and has been doing this since 1986. In that time they’ve been huge advocates for teaching STEM education long before there was ever an S-T-E-M acronym. With that, they created special education packages ideal for tech ed, vocational and advanced manufacturing programs. The size and scale of these machines have been designed to fit Middle and High Schools up through the technical colleges, universities and research institutions. A CNC router is a vital part for many manufacturing processes and a Techno CNC router can be an affordable, yet motivating STEM teaching solution for your program.

BT1212 Benchtop CNC Router

- Precision ball screws on all three axes

- 800 Watt (1 HP) Kress variable speed spindle 8,000-24,000 RPM

- Brushless micro stepper motor control system

- Aluminum T-slot table

- Compatible with G code and M codes

- Cast metal base construction

- Easy to learn and operate

- Includes: 1/8″, 1/4″ collets and wrenches

HD Mini CNC Router

- 23″ x 35″ Process area

- Precision ball screws on all three axes

- 2 HP HSD high frequency collet spindle

- Brushless micro stepper motors and controls

- Aluminum T-slot table for easy part fixturing

- Automatic tool calibration pad

- THK rails and bearings

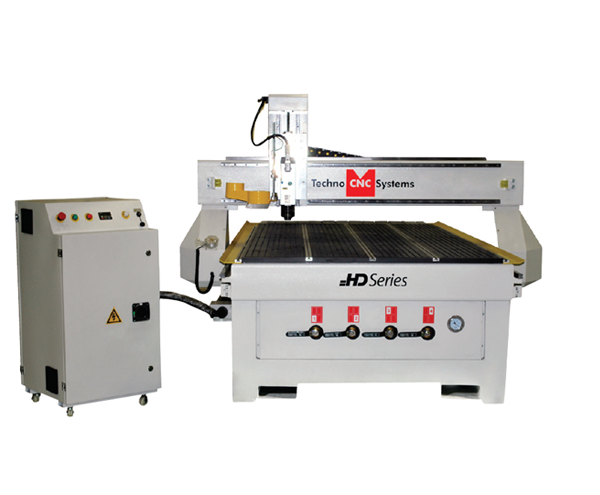

HD CNC Router

- 4 HP HSD high frequency collet spindle

- Maintenance free high precision brushless stepper drive motors

- Automatic tool calibration pad

- 4-zone vacuum T-slot table

- Easy-to-use hand-held micro stepper controller

- Open architecture works with all industry standard CAD/CAM software

CNC Plasma Cutter

- 2′ x 2′, 4′ x 4′, 4′ x 8′ and 5′ x 10′ sizes

- Unique design, easy to learn and operate

- Welded steel frame construction

- Precision helical rack and pinion on X and Y axes with ballscrew on the Z axis

- Magnetic torch breakaway with auto Z-axis retract

- Brushless micro stepper motors and drives

- High-speed cutting up to 800 IPM

- Compatible with industry standard G Code files

- Plasma table: Steel V-grid down draft

- Automatic torch height control (THC)

- Multiple torch options available

HDS CNC Router

- 12 HP HSD automatic tool changer spindle

- Maintenance free brushless Delta AC servo motors and drives

- Automatic tool calibration pad

- 4-zone vacuum T-slot table

- 8-position tool rack

- Pneumatic material placement stops

- Osai industrial AC servo controller

- Hand-held pulse generator

- Easy to use Techno CNC Interface

- Open architecture works with all industry standard CAD/CAM software

Venture CNC Router

- 12 HP HSD automatic tool changer spindle

- Maintenance free brushless Delta AC servo motors and drives

- Automatic tool calibration pad

- 4-zone vacuum T-slot table

- 8-tool rotary carousel

- Pneumatic material placement stops

- Osai industrial AC servo controller

- Hand-held pulse generator

- Easy to use Techno CNC Interface

- Open architecture works with all industry standard CAD/CAM software

Venture Plus CNC Router

- 12 HP HSD automatic tool changer spindle with 8-position rotary carousel

- Maintenance free brushless 1.5 kW AC servo motors and drives

- Precision helical rack and pinion on X and Y axes with ballscrew on the Z axis

- 4-zone vacuum T-slot table

- Pneumatic material placement stops

- Hand-held pulse generator

- PC based Osai industrial CNC controller

- Open architecture works with all industry standard CAD/CAM software