Stratasys Demonstrates Advantages of Additive Manufacturing for Aerospace Tools, Prototypes and Final Parts at 32nd Annual Space Symposium

By Scott Sevcik, Director, Aerospace and Defense, Stratasys

Space Symposium is the only event where you find NASA Administrator Charles Bolden, Bill Nye the Science Guy, Buzz Aldrin and Jeff Bezos on the same agenda. It’s an event filled with CEOs and VIPs and features some of the biggest announcements in the industry. This year, Blue Origin launched a reusable rocket for a third time, and SpaceX succeeded in landing a rocket on a barge in the days leading up to the event.

The 32nd annual Space Symposium was held at the historic Broadmoor in Colorado Springs, and the industry is showing how dynamic it is. New capabilities and markets are opening in the commercial space, there is renewed focus in the civil market – driving science and exploration to new heights. To achieve these lofty aims, there are new technologies being brought to bear – decreasing cost and increasing utility in the industry. 3D printing is one of the technologies supporting this period of aggressive innovation in aerospace.

This is the second consecutive year that Stratasys has been invited by United Launch Alliance (ULA) to participate in their exhibit, and is also the first appearance for a Stratasys booth. In the year since the last Space Symposium, we’ve had the opportunity to highlight how ULA has adopted Stratasys FDM 3D printing solutions and ULTEM 9085 material in some very innovative ways.

Last year, ULA discussed how they undertook flight-qualifying 3D printed thermoplastic parts, and the millions of dollars they would save from consolidating parts and replacing aluminum with plastic. Flight qualification led to flight hardware on March 23rd of this year, when the Atlas V OA-6 launch carried the first serial production 3D printed thermoplastic parts on a launch vehicle.

Download our White Paper on Additive Manufacturing Trends in Aerospace

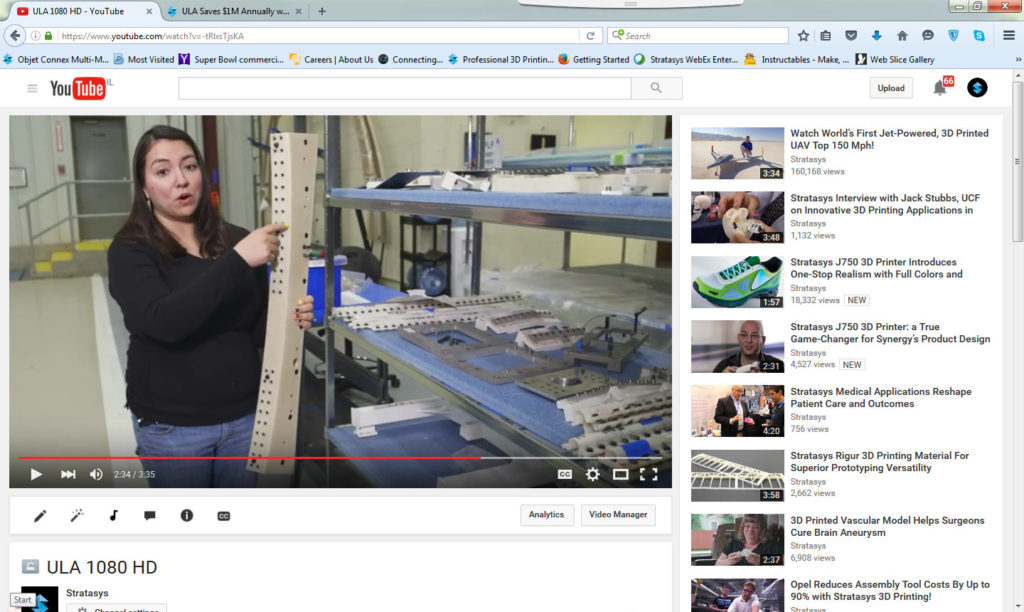

Now, in this new video, we have an opportunity to share a more in-depth look at how ULA is adopting 3D printing throughout the organization. From the introduction of rapid prototyping, to the efficiency they have gained on the factory floor through the use of more than 300 3D printed tools, to innovative new designs for the next generation Vulcan rocket.

“When we initially got our first Fortus 900mc 3D Printer, we did a lot of prototyping, models and mock-ups. Then it involved into a more of a tooling usage, where the factory production engineers and technicians are actually using the tools to build the rocket parts…we’ve been able to print over 300 production tools that have made our launch vehicle production operations more efficient,” said Greg Arend, Additive Manufacturing Development Leader, United Launch Alliance.

“Recently, additive manufacturing has allowed us to redesign propulsion components. Taking advantage of the open design box of additive manufacturing, we were able to come up with a part that was cheaper, lighter and actually performed better than the original part,” explained Matthew Perry, Composite Design Engineer, ULA.

ULA is not alone in 3D printed aerospace. Because of typical low production volume requirements, 3D printing is an excellent fit for the space industry for both tooling and production part applications. More than tools and parts, our ability to develop 3D printing materials engineered to our customers’ most challenging requirements was recently demonstrated by NASA’s use of a custom developed ESD-PEKK material for parts on the ICESat-2 vehicle.

“Stratasys has been invaluable to us from a material development process. It’s provided us with new options we didn’t have before for part design and very unique circumstances, so things like ESD capabilities, conductivity in plastics, and high aero-thermal performance,” said Perry.

With the growing ability of 3D printing to bring significant advantages to the space industry through cost-effective, low-volume production, and lighter, more complex parts, we’ll certainly continue to see more 3D printing firsts in space. And Stratasys will continue to lead the way in supporting the space industry in its most innovative pursuits – with an eye to the future and a meaningful industrial impact today.