How the Northeast is Continuing its Tradition of Industrial Innovation

How the Northeast is Continuing its Tradition of Industrial Innovation

New England has always been synonymous with the word “revolutionary”. Known as birthplace of the American Revolution, New England was home and hub to some of the most influential founding Fathers, a place with a storied history, steeped in tales of courage, conviction and ideas that dared to fly in the face of convention.

Fast forward to the next century – spurred on by a keen realization that the country must quickly gain a strong economic foothold in order to survive, New England became the birthplace of America’s Industrial Revolution.

Today, we are in the midst of another revolution.

This time a globally recognized Advanced Manufacturing initiative, coined “Industry 4.0”. New England once again is positioned as a hub for the manufacturing development of innovative products and groundbreaking production methods. Strong leadership and grant initiatives are enriching our education programs laying the foundation for future growth in manufacturing. Despite this, the skills-gap looms as a sobering issue, which threatens to inhibit the rapid growth in our manufacturing sector necessary to keep us competitive in the global marketplace.

The heartening news? That revolutionary mindset at the heart of meaningful industrial reformation is still is thriving here in New England, and with it the desire to be at the forefront of technological change. Two historical concepts in particular will go a long way to closing the dreaded skills-gap:

Apprenticeships

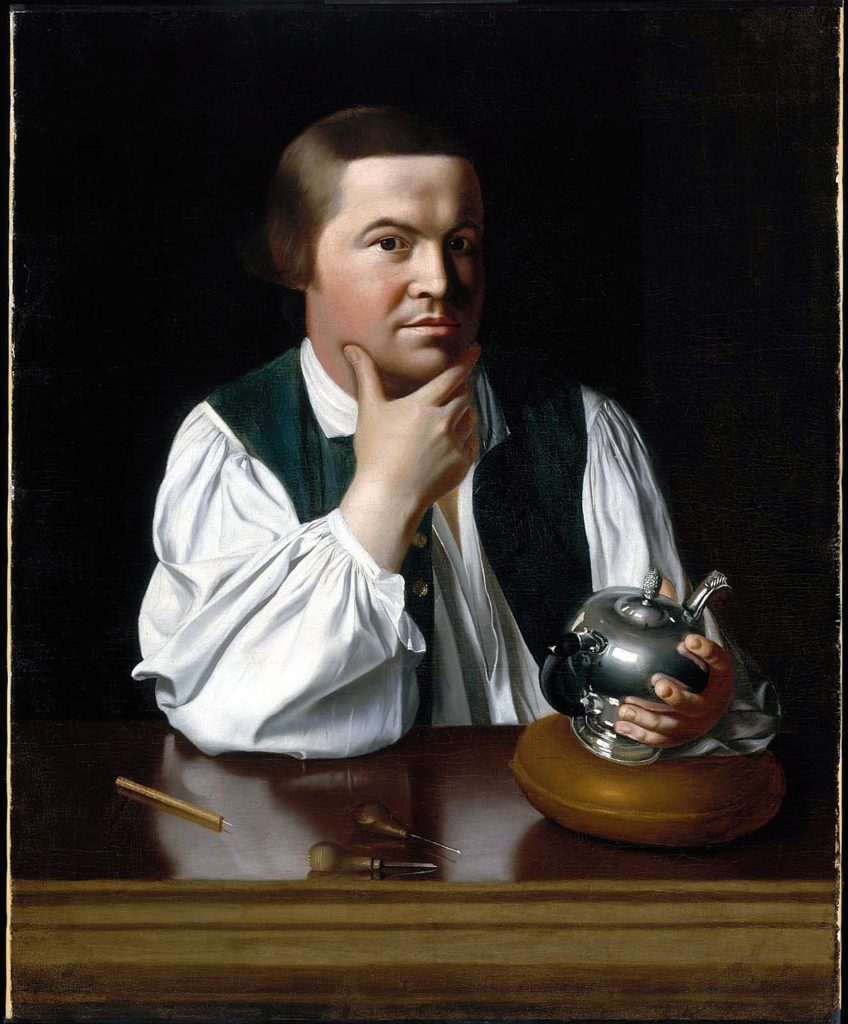

200 years ago – Paul Revere

200 years ago – Paul Revere

Well-known patriot Paul Revere, was more notably a master craftsman and industry leader of his time. Along with being a skilled silversmith, casting the first large scale bells made in America, Revere was an innovative manufacturist. Through perseverance he produced the first rolled copper sheets in the US. becoming a major supplier of copper for the US Navy fleet which included nails, bolts, spikes and sheathing. Trained as an apprentice to a silversmith himself, Revere “paid it forward” employing many apprentices himself. The concept of educating the next generation in skilled craftsmanship was understood to benefit and future-proof industry. By employing apprentices journeymen did their part to ensure that US manufacturing would grow rather than stagnate. Case in point: One of Revere’s apprentices, William Cooper Hunneman, went on to start a company that manufactured the finest hand-pumped fire engines of the time.

Today

Just as education in the 1600’s focused on physical skills, educators are circling back to similar ideas about teaching life-ready skills. Realizing employers want to see evidence of what new workers can do, rather than what they profess to know, CTE programs in New England are being equipped as advanced manufacturing training grounds, such as at Diman Regional Vocational Technical School. Outfitted with industry-recognized manufacturing equipment, these labs include cutting edge technology such as production 3D printers, CNC machines, and engineering labs like PLC & robotics training modules. Conversely, industry & government leaders in New England are realizing the importance of growing apprenticeship opportunities for area students in efforts order to fill the skills-gap. Apprenticeship initiatives in Massachusetts paired with the investment of Skills Capital grants for CTE schools are enabling students to learn valuable real-world skills preparing them for high paying advanced manufacturing positions.

Integrated Manufacturing

200 years ago – Visionary and industrialist, Francis Cabot Lowell

Mr. Cabot Lowell inspired after visiting textile factories in Britain, founded a hub for textile development along with innovative industrial practices, in Waltham, MA. Along with his partners in the Boston Manufacturing Company, introduced a power loom, based on the British model, with significant technological improvements. Later relocated to the banks of the Merrimac River in Lowell, MA, this center for manufacturing is considered by many to be the birthplace of the Industrial Revolution in the USA. From there, millyards began to flourish rapidly throughout New England bolstering the economy of the region and its citizens. In later years, due to offshoring & relocation, manufacturing dwindled and these once thriving industrial spaces become vacant reminders of years past.

Today

A revitalization of mill buildings, once again inhabited by innovators in manufacturing & technology sector are serving as incubators for new manufacturing start-ups. One such space is UMass Lowell’s Innovation Hub which features Stratasys 3D Printers & and cutting edge Epilog Laser machine installed by our technical advisors. With a membership, budding entrepreneurs and students from UML & the surrounding communities have access to this FabLab. Schools are equipped with similar labs and advanced manufacturing tools are igniting sparks of innovation in their students. Rapid development processes are here in industry, with products being designed with CAD/CAM & 3D Scanning Technology & Reverse Engineering, prototyped with desktop metal & plastic 3D printing, and produced with revolutionary 5-axis CNC machines, and etched on spot using fiber fusion laser technology.

New Outlooks for Modern Manufacturing

As much as our manufacturing heritage inspires us, new ideas and a global outlook are fueling the imagination of advanced manufacturing leaders of tomorrow. Whereas old factory jobs and traditional products emphasized the standardized and routine, the factory of the future is propelled by agility and innovation. In Industry 4.0 factories, engineers and production workers put their heads and hands together to understand the job and the product from all angles. The result? A streamlined production process with less waste, orchestrated with and driven by data collected by sensors into iOt, and assisted by automation & robotics.

European companies such as the Germany’s FESTO are blazing the trails and helping bolster US companies in the process. Through apprenticeship model well supported in Germany, FESTO is training students throughout the US to compete in an automated world on advanced robotics & PLC training systems. As sponsors of SkillsUSA, FESTO coordinates mechatronics competitions throughout US. FESTO certifications & training workshops are available to AET Labs customers, and our training advisors are keen to help educators in New England install & educate instructors about these cutting edge training systems.

We proudly represent leaders in the advanced manufacturing training products & tools – FESTO, KUKA Robotics, Stratasys, EMCO, & Epilog Laser to name a few. In partnership with these industry leaders, we offer PD workshops & certifications for our customers and the N.E. education community:

FESTO Mechatronics training

Advanced 3D printing Workshops

Laser- Cutting & Engraving Workshops

Seimens CNC certifications

FESTO Industry 4.0 certification

KUKA Robotics Certifications

If history tells us anything, fearless innovation is where success lies, and New England is where it’s at! At AET Labs we’re thrilled to be playing a supporting role in Industry 4.0 education, and Advanced Manufacturing initiatives in schools throughout Massachusetts, New Hampshire, Rhode Island, Connecticut, Vermont, and Maine.