As the manufacturing industry in Massachusetts continues to evolve and thrive, preparing students for careers in this dynamic field is crucial. The Manufacturing Innovation Pathway provides opportunities for students in Massachusetts high schools to gain the skills and knowledge they need to work with local companies. By integrating cutting-edge equipment and certifications into your curriculum, you can attract students to your program and give them hands-on experience that aligns with industry expectations. Let's explore technologies to incorporate into your Manufacturing Innovation Pathways program.

What is the Manufacturing Innovation Pathway?

The goal for Innovation Pathways under Governor Maura Healey's administration is to help "reimagine high school" by engaging students with hands-on learning for in-demand career paths. Manufacturing is one of six industries in the Innovation Career Pathways program due to the demand for skilled employees in Massachusetts in these areas.

Any high school in Massachusetts can apply to become an Innovation Pathways designated school. The Part A planning grant provides funding to support applicants in the preparation of their Innovation Career Pathway designation application materials. The Part B implementation grant helps fund the execution of the approved plan, including curricular development, professional development, instructional-related supplies and materials, and industry-recognized credentials.

Considerations for Selecting Equipment for the Manufacturing Innovation Pathway

Collaboration with local companies and industry partners like MassHire are required to become a designated Innovation Pathways school. Your curriculum and equipment need to reflect skills for your local job market.

Finding equipment that gets students excited to want to participate in your program is also beneficial. Current cutting-edge technologies like desktop robots give students immediate results because they are quick to learn. Providing opportunities for students to receive industry-recognized certificates alongside using equipment will also motivate them. Meeting with local employers and finding out what equipment they use will help guide your classroom equipment selection.

Recommended Equipment for the Manufacturing Innovation Pathway

We recommend exploring some of these certifications and equipment for your program to give your students real-world skills to contribute to the Massachusetts workforce.

CNC Machines

Students learn the CAD to CNC workflow by using these machines, with an opportunity to receive an industry-recognized certificate.

Tormach CNC Industry Certification

3D Printers

Students can see CAD designs come to life through 3D printing and get experience with the prototyping process using different materials. For more advanced instruction, students can also get a NOCTI certification in additive manufacturing.

Stratasys F70 3D Printer

Laser Systems

Laser cutters are easy ways for students to create prototypes to build projects with low-cost materials.

Robots

Teaching robotics provides an interactive way for students to learn about automation and its role in manufacturing.

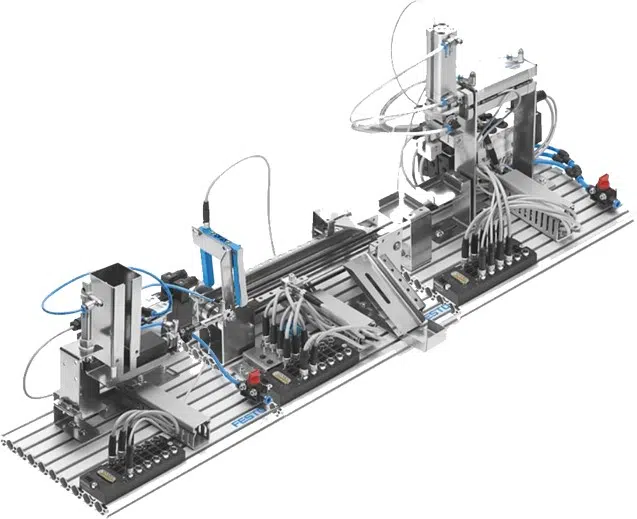

Mechatronics

Students learn about automation technology and the fundamentals of mechatronics giving them hands-on experience in production technology with the Festo MecLab Trainer.

Funding Equipment for the Manufacturing Innovation Pathway

The second step to the Innovation Pathways application is to apply for funding to support the implementation of the initial grant proposal. New and existing Innovation Pathways programs are eligible to apply for awards up to $50,000 to $75,000 to fund equipment and other items.

What's Next?

Investing in the right equipment for your Manufacturing Innovation Pathways program enhances your school's curriculum and plays a pivotal role in shaping the future of your students and the local community. By providing access to advanced tools like CNC machines, 3D printers, and robots, you create an engaging and practical learning environment that prepares students for high-demand careers in manufacturing in Massachusetts.

Are you seeking guidance on your grant application or what equipment to use in your program? AET Labs has experience collaborating with many Innovation Pathways Manufacturing programs, including Fitchburg High School. Contact us today to get started!