The 3D Printing Challenge: Complex Cam & Piston Assembly

So, what allows a Stratasys 3D Printer to create these complex geometries where others fail? In a nutshell, it’s the following attributes that set them apart:

- Materials – ABS, ASA, PC-ABS, Ultem, Nylons. Just a few examples of the industrial thermoplastics Stratasys machines have been designed to work with for creating accurate and repeatable, high-strenth models

- Heated build chamber – To ensure the highest accuracy and stability througout the build process, the chamber is regulated to precise temperatures matched to each material.Think of it as a convection oven…

- Accuracy – To consistently build parts at +/- 0.005″, you need a machine designed to the highest specifications. The next time you see a prosumer machine, look at the z-stage or x-y gantry and then compare it to a uPrint or other Stratasys machine.

- Soluble Supports – As you’ll discover below, this is one of the greatest features of all. By embedding layers of filament that are dissolvable in a water-detergent bath, designers have the freedom to create complex assemblies with total hands-off post-processing

- Software – GrabCad Print is a simple, yet powerful method for slicing and processing toolpaths for all Stratasys 3D printers. Supports are generated automatically. For even greater toolpath control the Insight plug-in can be used with the F370 and Fortus machines.

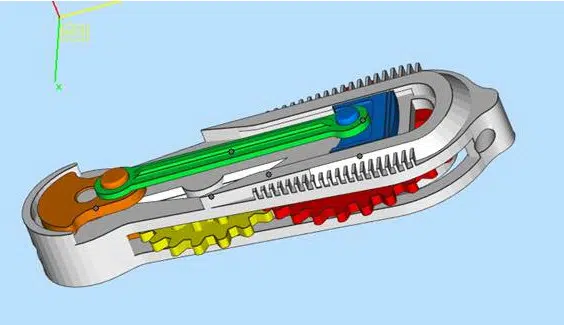

Created by Stratasys Applications Engineer Chris Wier, this dynamically operated cam and piston assembly (Fig. 1) is connected by three gears embedded within a complex geometric housing.

Fig. 1

By making full use of the Stratasys technology, toolpaths are generated using GrabCad Print. A support structure (noted in orange) is automatically created to support the model layers that overhang. (Fig. 2) Even bearings and shafts incorporate a 0.020″ surrounding layer of support.

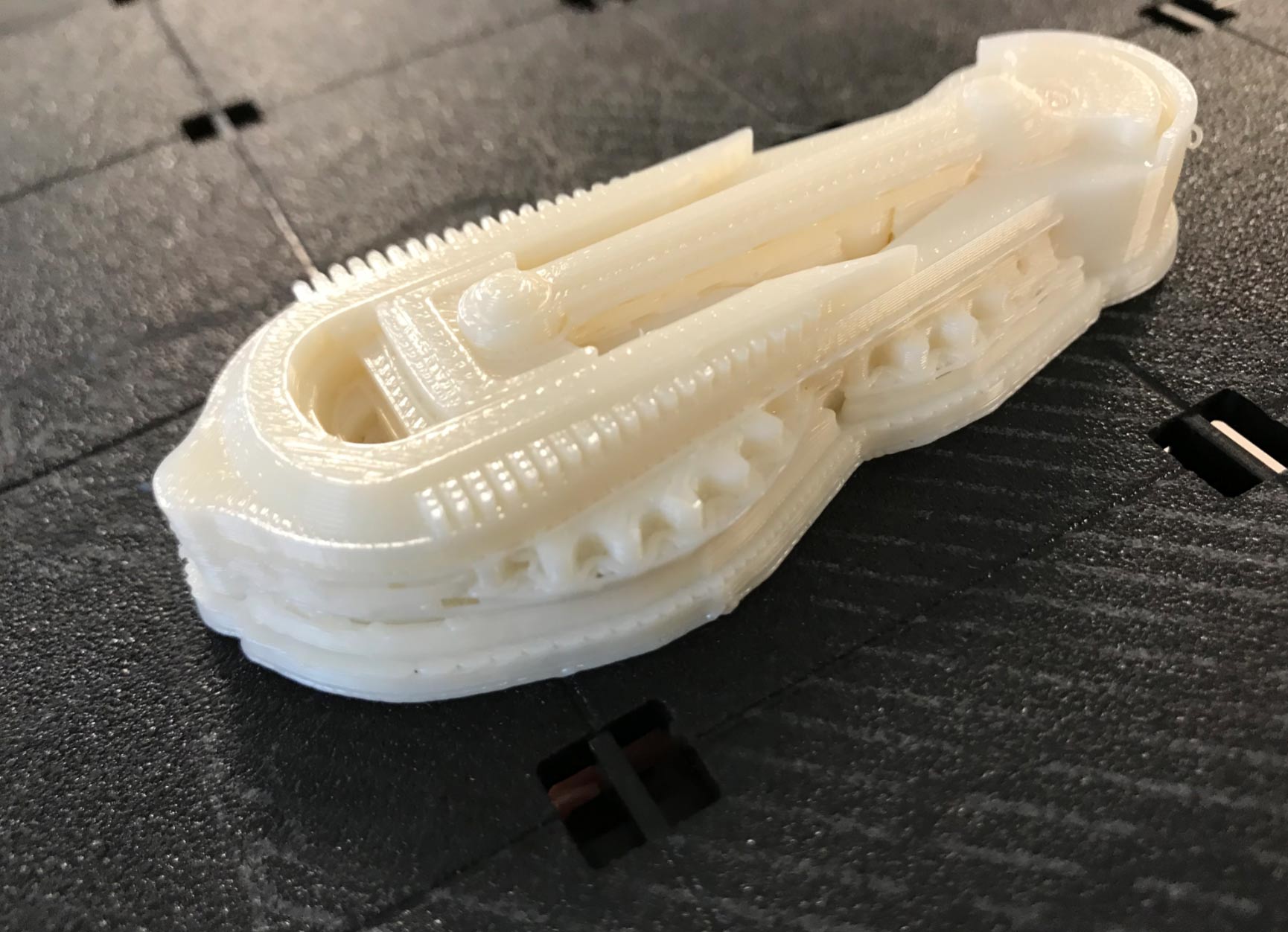

Fig. 2Support material surrounds the model when it first comes out of the printer. (Fig. 3) It is then placed in the wash station where the support material is automatically dissolved using an eco-friendly detergent.

Finished models come out of the wash station completely assembled, with full motion and conform to an accuracy of +/- 0.005″. (Fig. 4)

Side note: Although this part was printed on a Stratasys F370 machine, the same results can be achieved on a $5,999 Mojo!

…but don’t worry if your 3D printer can’t do this build. Just let us know and we’ll be happy to send you a working model!

Download this STL file and get started!